Contatto

Siamo a vostra disposizione da lunedì a venerdì dalle ore 8:00 alle ore 17:00. In questo link troverete le persone di contatto per la vostra regione.

Sede di Wolfurt

+43 5574 6706-0

Carrello acquisti {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Articoli Cambia carrello acquisti

Nota

| Foto | Articoli | Pz. | Prezzo singolo | Prezzo unitario | Prezzo unitario incluso lo sconto | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Clienti

- Costruzione stampi

- Stampi per tranciatura

- Costruzione macchine e dispositivi

- Progettisti

- Stampaggio ad iniezione

-

Prodotti

- Nuovi prodotti

- Portastampi

-

Basi portastampo

- La base portastampo standard SV

- Basi portastampo di precisione SP

- Base portastampo a due colonne con guida posteriore SH

- Base portastampo diagonale a due colonne SD

- Base portastampo centrale a due colonne SZ

- Tecnica modulare SM

- BASI PORTASTAMPO TRANCIA-PIEGATRICI SB

- Sistema di staffaggio H 3000

- Piastre P

- Barre N

- Piastre e barre

- Lavorazioni speciali

- Accessori E

- Tecnica del canale caldo

- Termoregolazione canale caldo

- Prodotti per l‘officina

- Azienda

- Carriera

- Servizio clienti

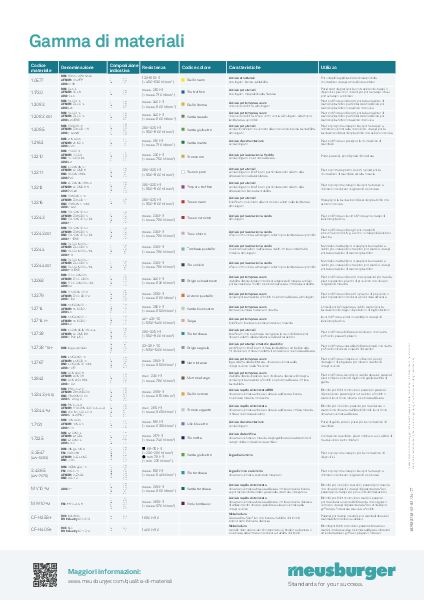

La nostra vasta gamma permette di trovare il materiale idoneo per quasi tutte le applicazioni.

1.2842 Steel for through hardening

Designation

| DIN: | 90 MnCrV 8 |

| AFNOR: | 90 MV 8 |

| UNI: | 90 MnVCr 8 KU |

| AISI: | ≈ O2 |

Chemical composition:

| C | 0.90 |

| Si | 0.20 |

| Mn | 2.00 |

| Cr | 0.40 |

| V | 0.10 |

Strength:

max. 230 HB

(≈ max. 780 N/mm²)

Thermal conductivity at 100 °C:

33 W/m K

Character:

steel for through-hardening with good machinability and high wear resistance; low warping and high dimensional stability; with high toughness and through hardenability (uniform hardness for cross sections 40 mm)

Application:

cavity plates and inserts exposed to abrasive stress; cutting punches; wear plates, cutting dies and guiding plates; guiding rails

Treatment by

unusual:

Polishing, etching, nitriding » 1.2379

is possible:

EDM, hard chroming

Heat treatment:

Soft annealing:

680 to 720 °C for about 2 to 5 hours; slow controlled cooling of 10 to 20 °C per hour to about 600 °C; further cooling in air, max. 220 HB

Hardening:

790 to 820 °C

Quenching in oil/hot bath

Obtainable hardness: 63-65 HRC

Tempering:

slow heating (to avoid forming of cracks) to tempering temperature immediately after hardening; tempering twice with intermediate cooling down to 20 °C increases the steel's toughness

max. obtainable hardness after tempering: 58−60 HRC

Annealing graph:

Technical tip:

- Steel grade 1.2510 is an adequate alternative with regards to its properties, machinability and dimensional stability after heat treatment

Vai alla panoramica per la costruzione stampi Vai alla panoramica per la costruzione stampi per tranciatura

Available in the web shop as:

Data sheet 1.2842

Azienda

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

N-Standard bars

N-Standard bars NP-Precision bars

NP-Precision bars NR-Round bars

NR-Round bars

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]