Tutto

06.08.2024 Guiding systems for die making

The guiding system is one of the most important components of a properly functioning die set. Meusburger offers a comprehensive, interchangeable range of bearing and sliding guides for a wide variety of applications. There are numerous combination options between guide pillars and guide bushes. The guides are also compatible according to DIN/ISO and optimally matched to the standardised Meusburger die sets.

14.06.2024 Durable and precise – ejector set guiding from Meusburger

25.04.2024 The multifunctional clamping system for mould making

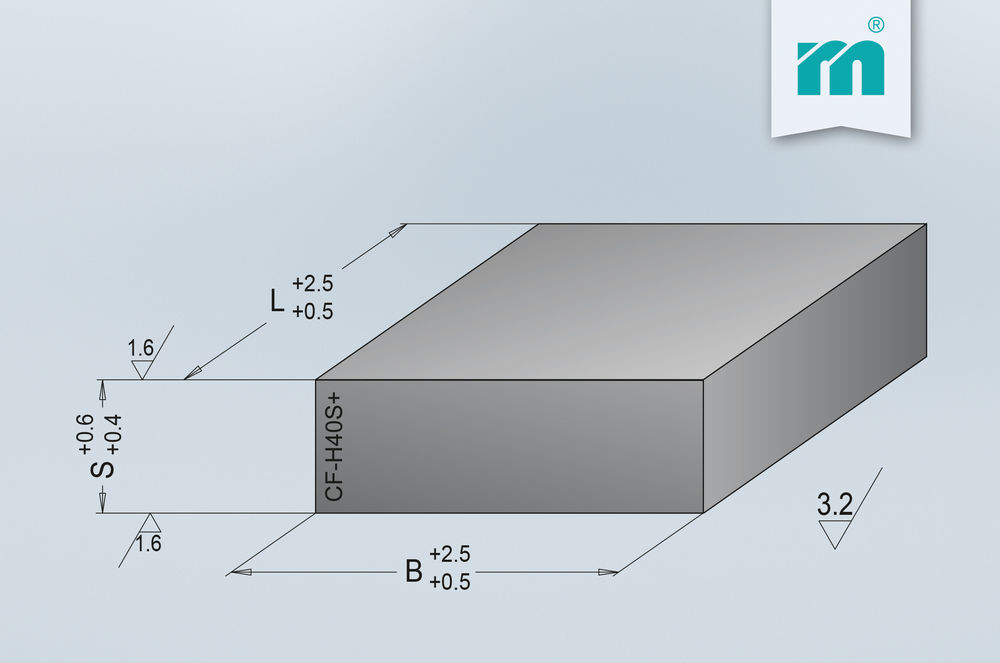

12.03.2024 The right material for every requirement in die making

To meet the different requirements for cutting steels used in die making, Meusburger has a large selection of eroding blocks that cover a wide range of materials, including classic steel for through hardening, high-speed steel, powder metallurgical steel and carbide. The eroding blocks are mainly used for the production of cutting punches and die plates and are available from stock in heat-treated and hardened versions. Their thicknesses are perfectly matched to the plates of Meusburger's standardised die sets and to the standardised lengths of the punches.

22.02.2024 Successo con le piastre della Meusburger

State cercando piastre di alta qualità? Come fornitore di normalizzati, la Meusburger vi garantisce il miglior supporto possibile. Con oltre 30 qualità di materiale stoccate su una superficie equivalente a oltre 2,5 campi di calcio e un'alta percentuale di produzione interna, non solo garantiamo la massima qualità, ma anche la sicurezza dei processi ed una disponibilità continua.

06.02.2024 Massima efficienza, grazie alle basi portastampo standardizzate

Grazie all'utilizzo costante dei normalizzati, è possibile risparmiare notevolmente sui costi di lavorazione. In particolare, i normalizzati di alta qualità della Meusburger costituiscono una base ottimale per la costruzione di stampi per tranciatura. Con le basi portastampo dell'azienda austriaca, i clienti beneficiano della massima precisione.

22.01.2024 Meusburger focuses on its core competences

Despite the demanding market conditions, the company is successfully overcoming the challenges and continuing to invest in order to offer its customers the best service and the highest quality. This year, the standard parts manufacturer will continue to focus on further optimising its core competencies in the area of plates and components to expand its position as market leader. Last year, the company was already able to support its customers as a reliable supplier thanks to its central location in the heart of Europe and its extensive standard parts warehouse. In 2023, Meusburger generated a turnover of 327 million euros.

12.01.2024 Single nozzle easyFILL EH 4010

28.11.2023 Configure cutting bushes quickly and easily

10.10.2023 Benvenuti al livello successivo – Entrate ora nel nuovo portale della Meusburger

Dopo un intenso periodo di preparazione, finalmente è arrivato il grande momento: il nuovo portale della Meusburger funziona parallelamente alla versione precedente. Il fornitore di normalizzati ha portato il suo mondo digitale ad un livello superiore, in modo che i suoi clienti possano raggiungere i loro obiettivi nel modo più rapido e intuitivo possibile. Il portale è facile da usare per chiunque ed il tutto con pochi click. E questo non è tutto, poiché il portale è in continuo sviluppo e in futuro offrirà ancora più funzioni. I vantaggi del nuovo portale sono riassunti di seguito.

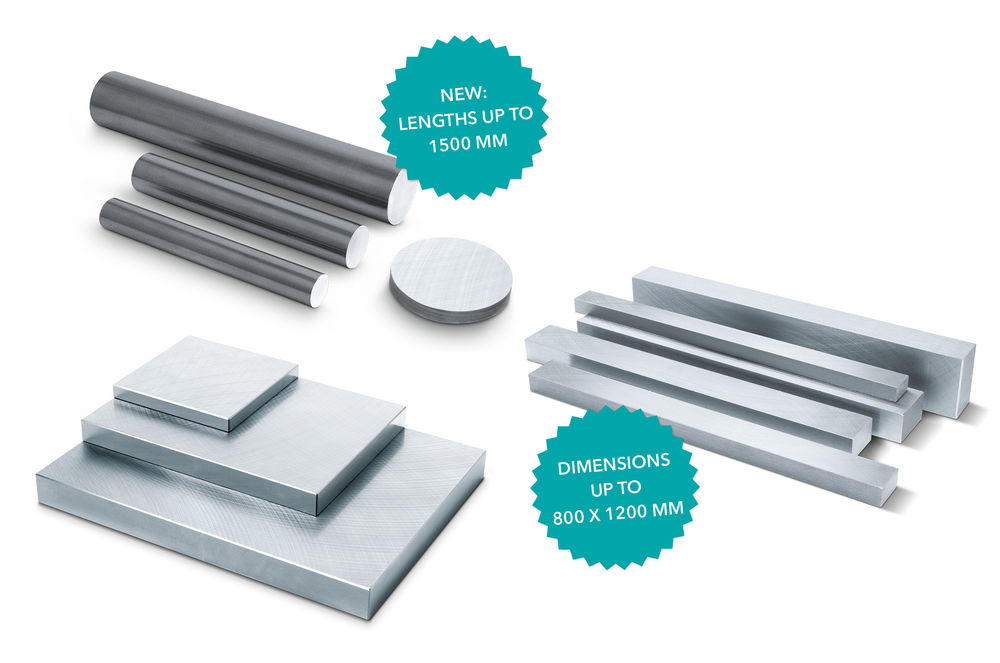

29.08.2023 Meusburger presents range at Fakuma

It’s time again – the international trade fair for plastics processing will take place in Friedrichshafen from 17 to 21 October. Meusburger will be attending and showcasing its product range at stands 2313 and 2316 in hall A2. Alongside its range for injection moulders, the wide range of components and the ENGEL injection moulding machine, the spotlight will be on the company’s latest campaign relating to bars.

22.06.2023 Componenti su misura

23.05.2023 Optimised set-up time thanks to multi coupler

Often there are long set-up times and unnecessary machine downtimes due to numerous temperature regulation connections. Not only time loss but also quality issues can also result through possible coupling errors. Meusburger offers the perfect solution for optimising set-up times with their system EU and USA multi couplers.

20.04.2023 Meusburger at the Moulding Expo with a new campaign

The Moulding Expo, the most important European event for the mould and die making industry, will take place in Stuttgart from 13 to 16 June 2023. Of course, Meusburger will be there again. In addition to its new products and a comprehensive range for injection moulders, the standard parts manufacturer will be presenting its latest campaign on cavities. Visitors will also be able to find out about standardised and customised solutions for hot runner systems. At the Meusburger stand E41 in hall 1, guests can even watch lunch boxes be produced live on an injection moulding machine from ENGEL.

13.04.2023 Le vostre cavità ci stanno a cuore

Alla Meusburger potete beneficiare di componenti di alta precisione e personalizzati in base alle vostre esigenze. Nella nuova campagna del produttore di normalizzati, potete scoprire di più sui prodotti riguardanti le cavità presenti nella gamma e sul perché la Meusburger offre sempre ottimi consigli. L’azienda trasmette il messaggio centrale della campagna “Le vostre cavità ci stanno a cuore” in due creativi video.

07.03.2023 Maggiore qualità, grazie all’unità a carrello compatta raffreddata

16.02.2023 Easy to design thanks to the Meusburger colour codes

24.01.2023 Meusburger keeps getting stronger

After a turbulent year in 2022, Meusburger continues to be a reliable supplier in the mould and die making industry. Despite the challenges in the past year, the standard parts manufacturer has optimised existing processes and further advanced digitalisation. The company recorded a 16% growth in turnover, partly due to increased costs and resulting price increases.

13.01.2023 Precise temperature control with the profiTEMP IM

01.12.2022 The ideal basis for durable injection moulds

11.11.2022 La soluzione ideale per il vostro stampaggio a iniezione

Che si tratti di piastre standard, stampi a carrelli, portastampi intercambiabili o micro stampi, la Meusburger offre una gamma completa di prodotti. I clienti non solo possono approfittare della produzione di acciaio sottoposto a trattamento di distensione, ma anche di una veloce elaborazione dell’ordine, dalla richiesta alla consegna. Tutti i portastampi sono immediatamente disponibili in magazzino. Nell’ultima campagna, mediante tre slogan abbinati a dei brevi video, scoprirete cosa rende così unici i portastampi.

04.08.2022 La Meusburger presenta la gamma di prodotti alla fiera K 2022

Alla fiera K di Düsseldorf di quest’anno, che si terrà dal 19 al 26 ottobre, la Meusburger si concentrerà sui portastampi standardizzati. Inoltre, il produttore di normalizzati presenterà la gamma di prodotti per lo stampaggio a iniezione, nonché soluzioni standardizzate e personalizzate per i sistemi a canale caldo. Un’attrazione particolare dello stand C30 nel padiglione 1 sarà la pressa a iniezione della ditta ENGEL, che consentirà ai visitatori di assistere dal vivo alla produzione di contenitori per il pranzo.

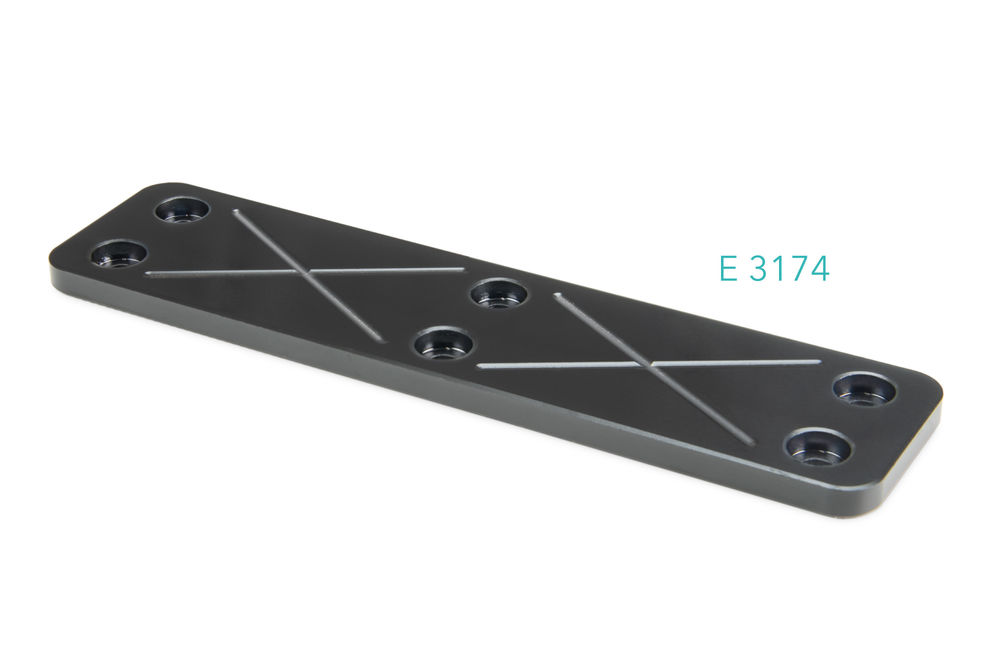

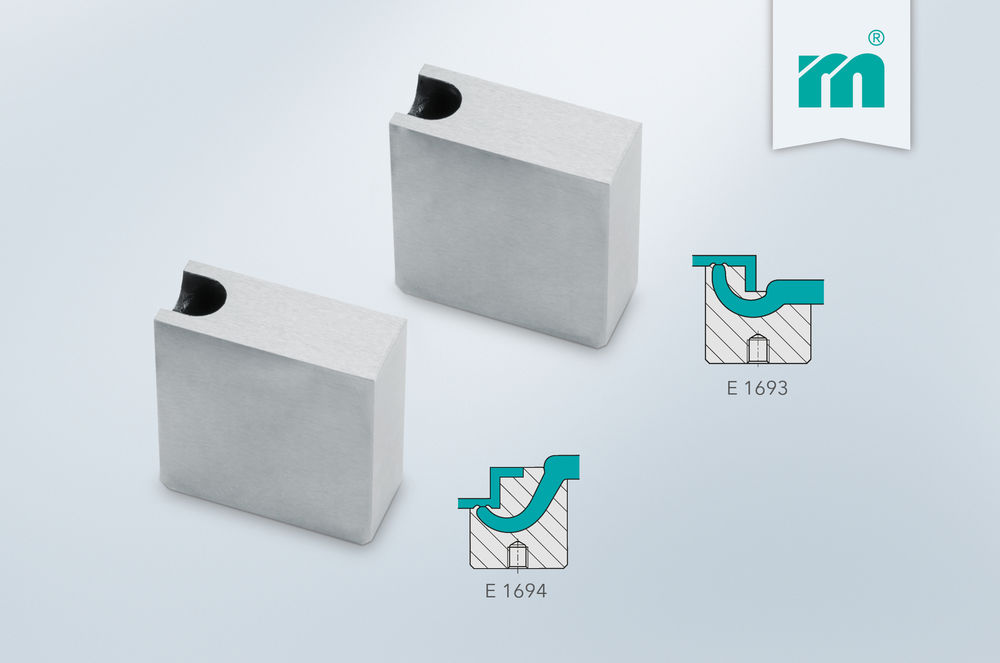

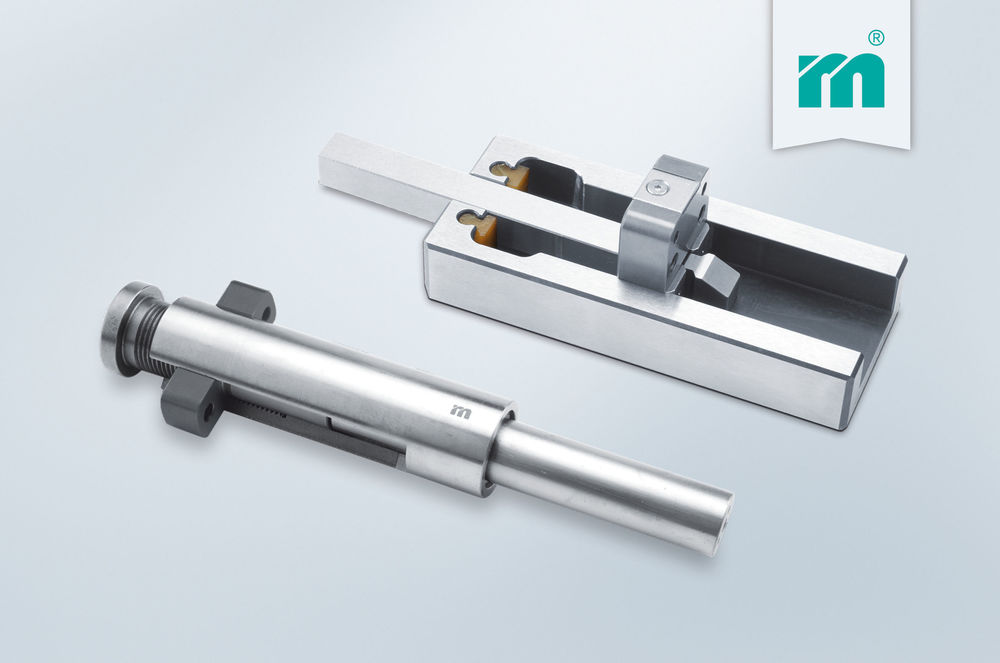

28.07.2022 Standardised components for strip guiding

Many stamping die components such as strip guiding are usually produced in small quantities, which is quite expensive and time-consuming. That is why using standardised components is a good option. Advantages include immediate availability, the combination possibilities of the different types of strip guiding within the stamping die, and the provided CAD data for the design. The following takes a closer look at the strip guiding solutions available at Meusburger.

28.04.2022 Diagnosi professionale con la profiTEMP TM

10.02.2022 Extensive range of springs at Meusburger

04.02.2022 Meusburger is ready for the future

2021 was complicated by both supply shortages and rising commodity prices, as well as limited customer visits due to the Covid situation. Despite these challenges, Meusburger was able to guarantee its customers continuous service and constant delivery availability. Thus, the standard parts manufacturer from Austria was able to achieve a turnover of 302 million euros thanks to the large warehouse and the high proportion of in-house production.

21.01.2022 Maximum closing force with the powerMOVE

The powerMOVE lever operated lifting plate is an integral part of the hot half in our range of valve gate systems. Matched to the sizes in the plates range, various standardised powerMOVE units are available, which are customised according to the individual requirements. The arrangement of the nozzles can be freely configured.

11.01.2022 Novità alla Meusburger nel settore dei prodotti per l’officina

Nell’autunno 2021, la Meusburger ha ampliato nuovamente la gamma di prodotti per l’officina. Saremo lieti di presentare ai nostri clienti numerose novità in quasi tutti i settori. In particolare, abbiamo ampliato la gamma di prodotti nei settori della tecnica di montaggio, del materiale ausiliario e della tecnica di staffaggio per l’elettroerosione.

11.11.2021 Meusburger guarantees supply security despite the crisis

22.10.2021 Meusburger highlights at Fakuma

From the 12–16 October Meusburger was represented at Fakuma, the international trade fair for plastics processing in Friedrichshafen, Germany. The range for injection moulders as well as the standard and custom hot runner systems were in the spotlight. The visitors in hall A2 at stand 2313 and 2317 also got the first look at Meusburger’s brand new trade fair stand design. Another particular highlight at the stand was the Engel injection moulding machine, which visitors were able to watch live in action producing bread boxes.

21.09.2021 Low-leakage couplers – for flawless and reliable temperature regulation in cleanrooms

15.07.2021 La molla corretta per il vostro progetto

Nella vasta gamma di molle della Meusburger trovate il prodotto adatto per ogni occasione, dall’utilizzo con carichi molto bassi all’utilizzo con carichi estremamente elevati. Per semplificare al massimo il processo di progettazione, all’inizio dell’anno la Meusburger ha introdotto un assistente per la selezione del sistema di molle a compressione adatto. Questo è di facile utilizzo, intuitivo e consente di selezionare la molla con pochi click. Inoltre, i dati in 3D configurabili possono essere scaricati.

29.06.2021 Optimal gate temperature control made easy

01.06.2021 Meusburger guarantees continuous delivery availability even during the raw material crisis

The current sharp increase of raw material prices is causing uncertainty for many companies. The dramatic rise in costs is due to the increasing demand for steel which has resulted in a global steel shortage. This has caused not only supply bottlenecks but an extreme increase in prices. For example, the price for steel grade 1.1730 has doubled. From today’s perspective, it is unclear when the situation will ease again.

22.04.2021 Sigillatura affidabile e rispettosa dell’ambiente

30.03.2021 Standardisation in the hot runner sector with the FH mould

In today’s world, standardisation plays a major role for successfully operating a company in most industries. This also applies for the hot runner sector where substantial time and savings potentials are possible through standardisation. The FH hot runner mould from Meusburger is the perfect example. It consists of a complete mould base including a hot runner system.

23.02.2021 10 years of standardisation in die making

14.01.2021 Innovative solution for optimal slide retention

Slide retainers are needed to hold slides securely in the end position when the mould is open. With the new E 3050 leaf spring roll stopper, Meusburger has created an exclusive and cost-effective alternative to existing solutions on the market. The compact design enables retaining forces of up to 140 N and is therefore also ideal for holding large slide bodies in their end position. In order to cover a wide range of applications, the leaf spring roll stopper is available in two different variations and three different leaf spring thicknesses.

10.12.2020 La piastra adatta per ogni progetto

29.10.2020 Novità alla Meusburger nel settore dei prodotti per l’officina

Per poter soddisfare al meglio le esigenze dei clienti, la gamma di prodotti della Meusburger viene costantemente ampliata, come già avvenuto a metà ottobre per i prodotti per l’officina. Nel settore della rifinitura delle superfici, della tecnica di staffaggio e della tecnica di montaggio sono stati aggiunti nuovi prodotti. Inoltre, abbiamo ampliato anche la vasta gamma di prodotti per l’asportazione truciolo e degli accessori per l’elettroerosione.

16.10.2020 Risparmiate tempo e costi con il nuovo configuratore di staffaggio

Secondo uno studio, un’azienda costruttrice di stampi impiega in media 600 ore all’anno per l’installazione e la messa in funzione di ogni singola macchina. Mediante l’utilizzo di un sistema di staffaggio a punto zero, è possibile ridurre notevolmente questo tempo. Come rinomato fornitore di piastre, la Meusburger offre un ulteriore servizio. I clienti possono ora ordinare le piastre da lavorare con i fori calibrati già inseriti per i perni di staffaggio del proprio sistema di staffaggio a punto zero. L’ampliamento della nostra gamma di prodotti renderà la lavorazione delle piastre ancora più efficiente.

22.09.2020 Meusburger provides tried and trusted CAD tool free of charge

Together with their customer Schmidt WFT, Meusburger has developed a CAD tool that is now available to you free of charge. This tried and trusted tool is coordinated with the Siemens NX CAD system and enables designers to carry out a simple and time-saving design process. Configurations of components which are native in the system can be selected and all parameters are automatically adjusted. Installation spaces and the colour table standards developed by Meusburger together with the Association of German Tool and Mould Makers are also integrated in the tool. The parts list is automatically updated when changes are made.

01.09.2020 Quick & easy to replace: the guide pillar with conical shank

24.07.2020 TT slide unit now available in two new sizes

In addition to the existing sizes with slide surfaces of 12 x 10 mm and 15 x 12 mm, the tried and trusted E 3310 TT slide unit from Meusburger has been expanded with two new sizes with slide surfaces of 8 x 6 mm and 18 x 14 mm. The ready-to-use slide unit reduces overall costs during design and mould manufacturing. In addition, daily work is facilitated through the compatibility of the components and the direct download of CAD data including installation spaces. Small slide units are in particular demand for complex moulds.

07.07.2020 I rivestimenti incrementano la durata dei punzoni per tranciatura

L’usura abrasiva e adesiva che si verifica sul punzone durante il processo di tranciatura, viene minimizzata grazie ai rivestimenti. Questo porta ad un significativo aumento della vita utile dei punzoni e quindi anche ad una riduzione dei tempi di fermo macchina. Inoltre, grazie al coefficiente di attrito minimo, si riducono le forze di retrazione. A seconda del materiale da tranciare, vengono utilizzati diversi rivestimenti. Qui sotto trovate una panoramica dei rivestimenti più comuni, con le loro rispettive proprietà e campi di applicazione.

25.06.2020 Build-in cylinder with flange – new diameter available from stock

Meusburger offers the compact build-in cylinder with flange ideal for the smallest installation spaces. Thanks to uncomplicated incorporation and the supplied screws, it can be installed in no time at all. In addition, the two-step installation hole protects the sealing during installation. New in range is the build-in cylinder with flange with a piston diameter of 20 mm.

04.06.2020 Sintered iron in die making – the strong alternative

In addition to the classic materials for sliding guides such as steel and bronze, sintered iron has long been regarded as a strong alternative in die making. Thanks to its porosity, it is ideally suited for use as a slide bearing. It also offers high wear resistance and has very good emergency operating features.

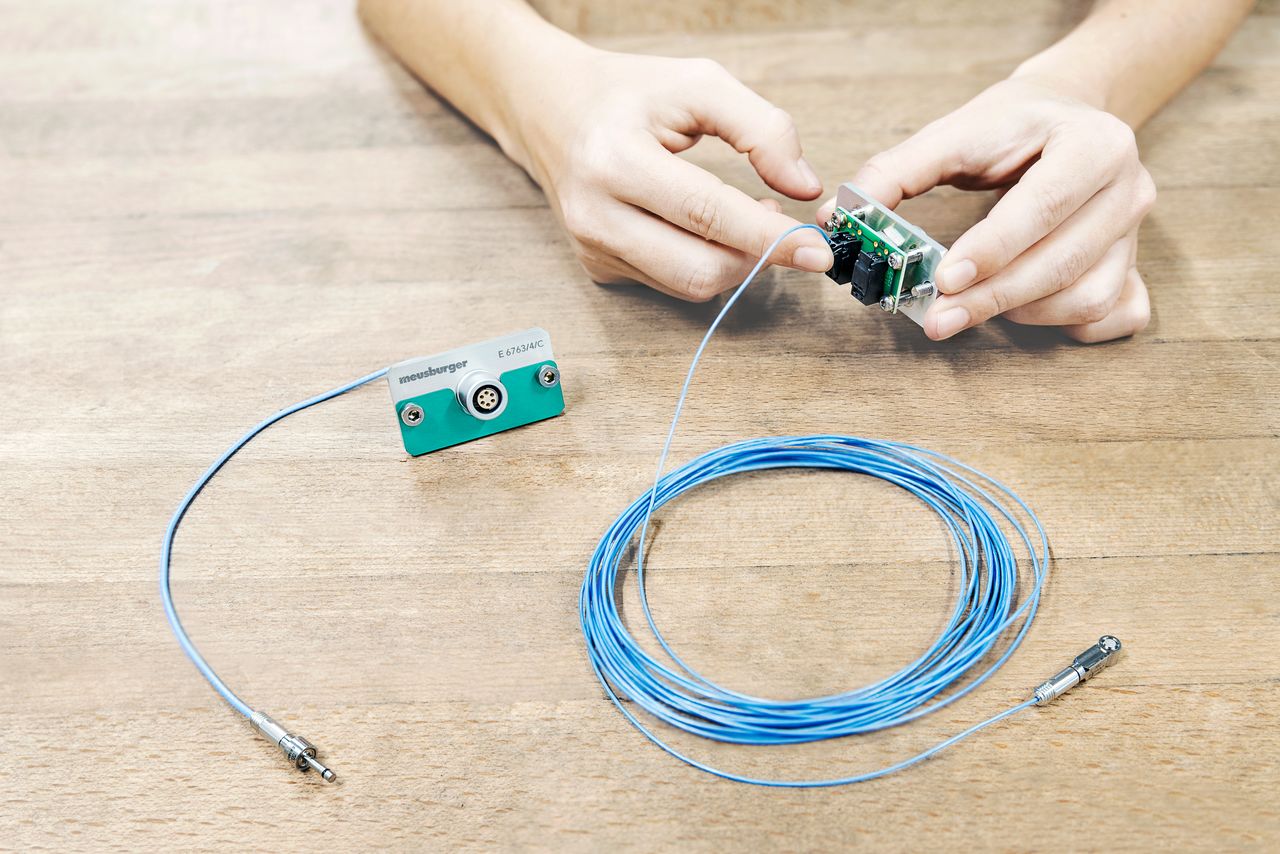

15.05.2020 Cavity pressure sensors: single wire vs. coaxial

The cavity pressure is an important parameter in process monitoring during plastic injection moulding. Pressure sensors are therefore indispensable for comprehensive mould monitoring. The use of high-quality piezoelectric sensors leads to optimal process quality and increases part quality sustainably. Two different technologies are available on the market for charge transfer: single wire and coaxial cables. We will show you the essential differences and characteristics of these two variants.

30.04.2020 Attrezzo di staffaggio premium della Meusburger per lo stampaggio ad iniezione

17.04.2020 Qualità di materiale 1.2738 TSHH immediatamente disponibile a magazzino

Specialmente in caso di stampi ad iniezione con un numero di colpi moderato, la riduzione dei tempi di lavorazione e l’ottimizzazione dei costi stanno diventando dei fattori sempre più importanti. Inoltre, una superficie impeccabile è spesso un requisito importante per i componenti stampati ad iniezione. L'acciaio 1.2738 TSHH si è affermato da tempo sul mercato per questo scopo ed è utilizzato specialmente nel settore automobilistico e in quello dei beni di consumo. La Meusburger offre ora piastre di forma e piastre normalizzate nella qualità di materiale 1.2738 TSHH, immediatamente disponibili a magazzino.

07.04.2020 The right material for every requirement in die making

To meet the different requirements for cutting steels used in die making, Meusburger has a large selection of NE blocks for eroding that cover a wide range of materials - including classic steel for through hardening, high-speed steel, powder metallurgical steel and carbide. The blocks for eroding are mainly used for the production of cutting punches and dies and are available from stock in heat-treated and hardened versions. Their thicknesses are perfectly matched to the plates of Meusburger’s standardised die sets.

10.04.2020 Il rilevamento della posizione garantisce un'elevata affidabilità dei processi

Position sensing plays an important role in a reliable injection moulding process. Whether for monitoring the end positions of a slide, ejector set or hydraulic cylinder – mechanical and inductive sensors have become essential in modern mould and die making. Here is an overview of the most common variations for position control of components in the mould.

06.02.2020 Elevata affidabilità nel controllo degli stampi a 3 piastre

I dispositivi aggancio-sgancio vengono utilizzati per controllare gli stampi con due piani di apertura, denominati anche stampi a 3 piastre. Con il nuovo dispositivo aggancio-sgancio E 1817, la Meusburger ha creato un’alternativa esclusiva ed economica ai prodotti esistenti sul mercato, come ad esempio i dispositivi di aggancio-sgancio piatto o tondi. Grazie al semplice principio di funzionamento meccanico, il nuovo dispositivo aggancio-sgancio offre la massima affidabilità nel controllo degli stampi a 3 piastre. Inoltre, il dispositivo è caratterizzato da un design compatto e bassi costi di lavorazione nel montaggio.

30.01.2020 Utensili di fresatura della Meusburger adatti per la lavorazione sul duro

Meusburger offers the optimal solutions for machining hardened material up to 67 HRC. The hard milling cutters in different variations achieve highest precision and quality. Most milling cutters are used in Meusburger’s own production. This means that the range is perfectly matched to the requirements and materials in mould and die making.

29.10.2019 Market innovations presented by Meusburger at the K trade fair

At this year’s K trade fair in Düsseldorf, the Meusburger stand featured the new configurator for hot runner moulds. The new cavity pressure sensors and many other Meusburger products were also presented to visitors, alongside the unmissable hot runner and control systems, WBI Knowledge Management and ERP software.

17.10.2019 Meusburger joins forces in 2020

24.09.2019 Meusburger alla Blechexpo 2019 con le nuovissime basi portastampo trancia-piegatrici

20.08.2019 Meusburger at the K 2019 with market innovations

At this year’s K trade fair in Düsseldorf (16 to 23 October), the Meusburger stand (hall 1, stand C30) will feature the new and one-of-a-kind configurator for hot runner moulds. In addition, the new cavity pressure sensors and many other Meusburger products will be presented. Of course the divisions of hot runner and control systems, Knowledge Management, and ERP will also be presented.

13.08.2019 A new generation of ejectors for inclined ejection units

For easier demoulding of internal undercuts in plastic parts, ejectors for inclined ejection units can often be used instead of slide units. With the new E 3270 Inclined ejection unit, Meusburger offers a cost-effective and ready-to-use alternative to the existing ejectors for inclined ejection units on the market. The part geometry is created with a block for eroding which allows for maximum design flexibility. The DLC coating of the ejector rod ensures minimal wear, best sliding properties and ultimately a long service life.

23.07.2019 Optimal materials for machining

16.07.2019 La Meusburger presenta le novità del settore prodotti per l’officina

A metà giugno la Meusburger ha ampliato la propria gamma di prodotti per l’officina con numerose novità ed estensioni nei seguenti gruppi di prodotti: asportazione truciolo, accessori per l’elettroerosione e tecnica di staffaggio. La Meusburger ha presentato inoltre i nuovi prodotti nel campo dei dispositivi di misura, degli elementi di trasporto e della rifinitura delle superfici.

25.06.2019 Basi portastampo trancia-piegatrici per le presse Bihler

Il fornitore di normalizzati austriaco Meusburger e l’azienda tedesca Bihler, specializzata in macchine trancia-piegatrici, presentano un’assoluta novità sul mercato. Dalla cooperazione tra le due aziende, sono nate le basi portastampo trancia-piegatrici standardizzate, realizzate con i normalizzati della Meusburger per le presse Bihler NC. Le nuove basi portastampo, nelle varianti „con fresatura di alloggiamento“ o con „premilamiera“, sono disponibili per presse di tranciatura con forze fino a 400 kN e dovrebbero consentire ai clienti della Meusburger e della Bihler un enorme risparmio di tempo e di costi in futuro.

18.06.2019 Misurazione della pressione della cavità per un’elevata efficienza dei processi nello stampaggio ad iniezione

Oltre ai normalizzati per il controllo della temperatura e della posizione finale, la Meusburger offre sensori per la misurazione della pressione della cavità. Questi ultimi sono compatibili con tutti i sistemi comuni di valutazione, utilizzando i cavi di collegamento compatibili. Nella gamma di prodotti sono disponibili due tipi di sensori per la misurazione diretta e indiretta. Inoltre, vengono forniti completi di accessori per il montaggio e cavo di connessione. I sensori sono immediatamente disponibili a magazzino, con i dati CAD da scaricare dallo shop online della Meusburger.

21.05.2019 Confronto tra le diverse modalità di fissaggio dei punzoni

La vasta gamma di normalizzati della Meusburger offre numerose possibilità di fissaggio per i punzoni, immediatamente disponibili in magazzino e con esportazione diretta dei dati CAD, per una rapida progettazione e produzione. A seconda del tipo di applicazione e delle circostanze, i punzoni possono essere montati e fissati in modo diverso nelle basi portastampo. In questo articolo, esamineremo più da vicino i diversi tipi di fissaggio per i punzoni, incluso il sistema Ball-Lock.

23.04.2019 Offset cutting punches at Meusburger

With the offset cutting punches from Meusburger there are many possibilities to configure the contour of cutting punches individually according to your needs. In addition, different materials and head shapes as well as coatings are available. These can be selected quickly and easily using the cutting punches configurator. Thanks to in-house production, Meusburger offers maximum precision and short lead times.

02.04.2019 Stampi a canale caldo in soli 5 minuti

Grazie al configuratore nuovo di zecca della Meusburger per gli stampi a canale caldo, con pochi clic può essere configurato un portastampo completo, incluso il distributore. Il configuratore si differenzia per l’elevata flessibilità, la creazione istantanea dei dati 3D e la visualizzazione immediata dei prezzi. Questa novità mondiale sul mercato è il risultato dell'ottima collaborazione tra la Meusburger e la PSG.

26.03.2019 The Meusburger Group at Moulding Expo 2019

At this year’s Moulding Expo in Stuttgart (21–24 May), the Meusburger Group’s stand (hall 7, stand C17) will feature the brand new and one-of-a-kind configurator for hot runner moulds. In addition, the new cavity pressure sensors and many other Meusburger products will be presented. The companies PSG, WBI and Segoni will also offer a glimpse into their product range.

16.03.2019 Design compatto grazie al cilindro di bloccaggio della Meusburger

26.02.2019 New embossing elements for die making

22.01.2019 Disponibili esclusivamente alla Meusburger: piastre di scorrimento con rivestimento DLC

18.12.2018 Tried and trusted components now available in stainless steel

Stainless steel components are mainly used in processing corrosive plastics or in clean room technology (e.g. medical or food processing applications). Meusburger has expanded its product range especially in the temperature regulation components, ejectors, and demoulding product groups with numerous new stainless steel components.

05.12.2018 Una standardizzazione efficace inizia dalla progettazione

Il mondo sta crescendo logisticamente ed economicamente. La globalizzazione aumenta la pressione competitiva nel settore della costruzione stampi e utensili e allo stesso tempo offre l’opportunità di approfittare di ordini in mercati in rapida crescita. Contemporaneamente, la spirale dell’innovazione sta girando sempre più velocemente, il che richiede adattabilità e flessibilità da parte delle aziende. L’elevata pressione dei tempi e dei costi, costringe le aziende ad un sviluppo costante in termini di efficienza. La standardizzazione ad alti livelli, lungo l’intera catena produttiva, offre un’eccellente opportunità di ridurre drasticamente i tempi e i costi di un progetto.

15.11.2018 5,000 new plates and bars sizes

09.10.2018 NEW from Meusburger: Blocks for eroding with starting hole

27.09.2018 Il trattamento termico corretto per il vostro successo

Not all stress-relieving heat treatment is the same – because only a proper heat treatment process ensures the desired result in the end. That is why Meusburger has been using its own furnaces for almost 30 years. Meusburger stands for top-quality products – only flawless steel from the best-known steelworks can make it through the quality check. Standard parts that are heat-treated for stress relief are right at the beginning of the die and mould making process chain and form the basis of high-quality moulds and dies.

13.09.2018 Problemi di tenuta in caso di elevate temperature?

In caso di elevate temperature, si possono verificare problemi di tenuta in diversi punti. Prima o poi, i tappi in ottone possono portare a delle perdite, con il conseguente arresto dei macchinari e lunghe pause per la riparazione. Di solito il problema viene attribuito al sigillante, nonostante la responsabilità ricada altrove: durante il riscaldamento e il raffreddamento infatti, si verificano dei cedimenti a causa del diverso coefficiente di dilatazione dei tappi in ottone e delle piastre in acciaio che, di conseguenza, portano alle perdite.

04.09.2018 Meusburger enables universal die set monitoring

The logic distributors by Meusburger in combination with the new limit switches with roller or dome plunger enable universal die set monitoring. The sensors of the limit switches are able to collect signals from different installation positions due to the adjustable roller. The manifold combines several of these signals without voltage drop. Simple and quick installation with maximum flexibility is ensured by the compact design and the many plug-in options.

23.08.2018 The Meusburger Group is represented at the Fakuma 2018

From the 16th to the 20th of October 2018, the Meusburger Group will be represented at the international trade fair for the processing of plastics in hall A2 at stand 2313 and 2317. With the motto ‘everything from a single source’, Meusburger, PSG, WBI and the youngest group member, Segoni will present new and tried and trusted products and services in the field of mould and die making.

24.07.2018 Meusburger presents the smallest ready-to-use slide unit on the market

The new member of the Meusburger family of compact slide units is the E 3310 TT-Slide unit, which features a compact design. The ready-to-use slide unit reduces overall costs during design and tool manufacturing. In addition, daily work is facilitated through the compatibility of the components and the direct download of CAD data including installation spaces. Small slide units are in particular demand for complex moulds.

12.07.2018 E 5636 Strip guiding rail in lengths 60 and 100 mm

10.07.2018 Stamps with latching function for even higher process reliability

Marking stamps are used for clear marking of injection-moulded parts. To prevent unintended movement of the arrow insert, Meusburger now offers stamps with a latching function. These ensure even higher process reliability during the injection moulding process, and prevent parts being marked incorrectly.

05.07.2018 Meusburger Group takes over Segoni

Wolfurt/Austria. The internationally active Meusburger Group with headquarters in Wolfurt will be taking over Segoni. The Berlin software specialist will continue as an independent enterprise, and all employees will be retained. In the coming years, long-term investments will be made in the further development of the software. Alongside the knowledge-based management method WBI, customers of the Meusburger Group will also be supported in the area of ERP/PPS through the digitalisation process.

28.06.2018 New catalogue for machine and jig construction

The hot off the presses Meusburger catalogue ‘Machine and Jig Construction 2019/2020’ is now available with numerous innovations. Customers will find the expanded product range on over 400 pages with 37,000 items clearly presented. The standardised and quickly available plates and bars are available in 29 different materials. And there is also a completely new product group: the components, which are specially tailored to the requirements of jig construction.

21.06.2018 La Meusburger presenta le novità del settore prodotti per l'officina

05.06.2018 A must-have in modern die and mould making: DLC coated components

08.05.2018 Novità nel settore della tecnica modulare

Alla Stanztec la Meusburger presenta novità esclusive per il settore della tecnica modulare. Le guide dei moduli E 5076 e E 5078 verranno fornite con lunghezze configurabili. Questo permetterà ai clienti una massima libertà di configurazione durante la progettazione degli stampi modulari. Con l’aiuto di inserimento i costi di lavorazione e i tempi di messa a punto verranno ridotti al minimo. Grazie all’assistente per la costruzione modulare, la selezione complicata delle singole piastre apparterrà al passato.

24.04.2018 NOVITÀ alla Meusburger: Cilindro ad incasso con flangia E 7048

La Meusburger offre in esclusiva il nuovo cilindro ad incasso con flangia, ideale per spazi di montaggio ristretti. Grazie alla semplice incorporazione e alle viti comprese nella fornitura, il cilindro può essere montato in brevissimo tempo. Inoltre, il foro di montaggio con due diametri diversi protegge le guarnizioni durante il montaggio.

22.03.2018 New cutting punches and contour bases at Meusburger

08.03.2018 The largest range of temperature regulation solutions for mould making

Meusburger is constantly expanding its range of temperature regulation solutions, which leads to a higher level of safety in operation as well as savings in time during the design and use. New in the range are temperature regulation components with sealant, plug-in type bridges and the Stäubli RMI Multi coupler system.

13.02.2018 Increased stamping process reliability with precision control devices

19.01.2018 High-quality steel for metalworking

06.12.2017 NEW from Meusburger: HFC rough milling cutters

The new high-feed milling cutters WZF 11512 and WZF 11522, or HFC milling cutters for short (HFC stands for High Feed Cutting), are mainly used for roughing. This procedure is particularly economical, as very high cutting speeds and feed rates can be reached. In addition, these milling cutters guarantee higher process reliability through a controlled wear process without cutting edge breakage.

21.11.2017 New from Meusburger: E 1307 Fine centring unit, flat for high-precision centring of inserts

The new E 1307 Fine centring unit, flat from Meusburger features minimal installation space which provides for maximum space utilisation within the insert. Through the DLC coated centring elements available with or without fixing holes the designer enjoys maximum flexibility during design, and the wear is reduced to a minimum.

24.10.2017 Die casting components for die and mould making

03.10.2017 Exclusive guide for inclined pin from Meusburger

The exclusive E 3064 Guide for inclined pin stands out due to optimal surface contact with the inclined pin and best material pairings. This results in a high force absorption. The machining of the pocket in the slide is possible without inclining. In addition the slide stroke can be adjusted subsequently by customising, or adjusting the position of the guide for inclined pin.

19.09.2017 Meusburger expands its range in the area of gas springs

04.09.2017 Merger of Meusburger and PSG China

29.08.2017 The Meusburger highlights at the Fakuma 2017

From the 17th to the 21st of October, Meusburger presents both the tried and trusted products and numerous innovations at the international trade fair for the processing of plastics. The precision cutting and grinding machine, the gear unit for stack moulds, and the high temperature hose are just a few of the product highlights that can be seen at the Meusburger stand no. 2313 in hall A2.

16.08.2017 Meusburger sets standards with the smartFILL single nozzles from PSG

The expert in standard components Meusburger now has the smartFILL single nozzles from PSG in range. Best part quality and a wide range of applications make the smartFILL hot runner single nozzle the poster child of PSG. By using this nozzle the melt is tempered homogeneously to the injected part guaranteeing highest quality of parts. With the easily interchangeable nozzle tips, different types of gating are possible which makes the smartFILL nozzles suitable for a wide range of applications and all common thermoplastics with and without fillers.

01.08.2017 Efficiency in machine and jig construction Meusburger at EMO 2017

From September 18th to 23rd 2017, EMO, the trade fair for metalworking, opens its doors in Hannover. Meusburger will also be represented this year in Hall 5 at Stand E 24 and informing visitors about its wide range of products as well as the advantages of standardisation in machine and jig construction.

18.07.2017 Meusburger now offers new guiding elements in the area of die making

04.07.2017 More safety in the operation thanks to the IsoTemp® high temperature hose

The new E 2187 IsoTemp® high temperature hoses from Meusburger combine tried and trusted technology with an innovative silicone sheath. This offers protection against burns as well as against abrasion or damages to the metal sheath. Therefore there is no risk of injuries from protruding wires. The special construction provides for high durability and maximum flexibility.

20.06.2017 Clamping devices for ergonomic work during polishing

Ergonomics plays a central role in the design of a safe and healthy working environment in many areas. With the new tiltable tables and magnetic clamping balls, which enable ergonomic work during polishing, the standard parts manufacturer expands its workshop equipment range and makes an important contribution for modern workplace design.

23.05.2017 Meusburger expands its range in the area of active parts

The standard parts manufacturer Meusburger now offers three new, innovative components in the area of active parts: a punch suspension piece with radius for fixing and installation of filigree punches, a block-shaped strip lifter with large contact surface and an additional size for the tried and trusted infeed guide for strip widths up to 152 mm.

09.05.2017 Double output thanks to the new Meusburger gear unit for stack moulds

25.04.2017 New configuration options for Meusburger cutting punches

The standard parts manufacturer Meusburger now offers new configuration options for cutting punches. This includes two different PVD coatings for maximum service life and the configuration of anti-rotation protection for shape punches. The cutting punches can be quickly and easily selected via the new configurator in the Meusburger digital catalogues.

28.03.2017 NEW from Meusburger: tunnel gate inserts for large contour steps

15.03.2017 Achieve maximum precision with the Meusburger guide pillar with centre collar

28.02.2017 NEW from Meusburger: magnetic proximity sensor and magnetic cable retainer

The standard parts manufacturer Meusburger expands its product range in the area of electrical components. The E 65620 Magnetic proximity sensor for T-slots with reliable and precise switching point is ideally suited for use as a cylinder sensor. For easy and secure fixing of cables within the moulds, Meusburger now also offers the universally usable E 2766 Magnetic cable retainer.

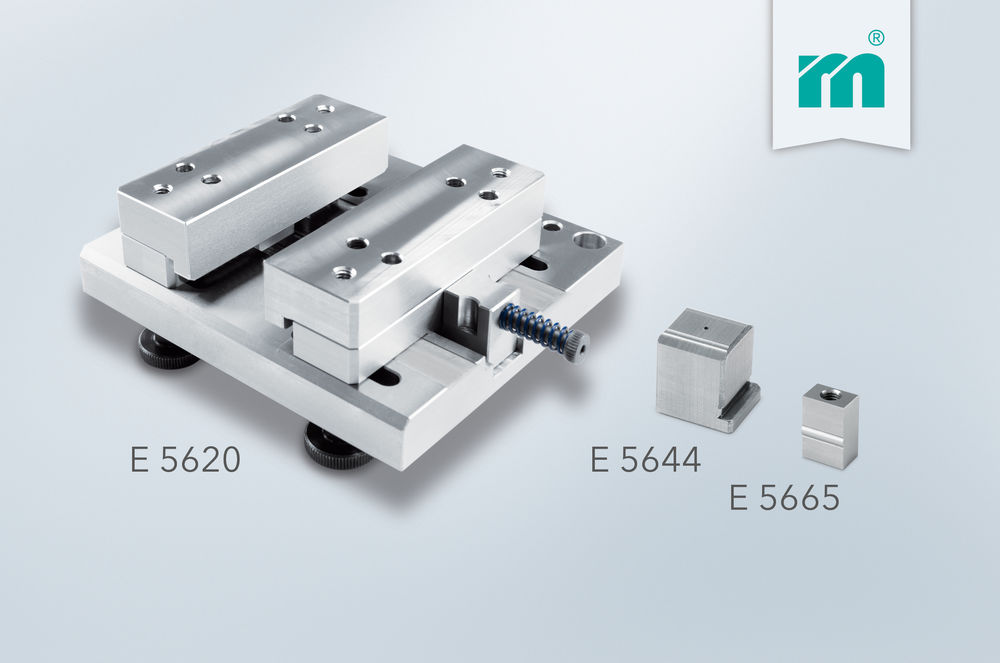

14.02.2017 Reliable clamping with Meusburger high-pressure clamping equipment

The standard parts manufacturer Meusburger expands its range of workshop equipment especially coordinated to die and mould making with high-quality high-pressure clamping equipment. In addition to the tried and trusted centring vices Meusburger now offers high-pressure vices in three different variations. Due to the integrated power amplifier a clamping force of up to 50 kN is reached. The repeatable accuracy during clamping is 0.01 and enables highest precision in the machining of workpieces.

18.01.2017 Meusburger hydraulic cylinders now with stroke of up to 200 mm

From now on the standard parts manufacturer Meusburger also offers hydraulic cylinders with a stroke of up to 200 mm available from stock. Thanks to the finely graduated stroke lengths a large application range is possible. Due to the standard lengths and transverse holes the double-acting cylinders can be flexibly installed.

03.01.2017 NEW from Meusburger - Adjustment unit with even more precise positioning

20.12.2016 Tried and trusted latch locks – now with DLC coating

06.12.2016 NEW at Meusburger – Compact and ready-to-use pilot unit

23.11.2016 NEW from Meusburger: flat-face centring unit with round fitting

Since October Meusburger offers a flat-face centring unit with round fitting. This innovative product in the range of Meusburger locks offers an additional option for a reliable and exact final centring of the mould at the split line face. Due to its geometry the new centring unit is optimal for moulds with unequal thermal expansion.

15.11.2016 NEW from Meusburger – carbide blocks for eroding

08.11.2016 Reliable demoulding of complex injection moulded parts

The compact ejector accelerator from Meusburger is the ideal device for the safe and targeted ejection of complex parts: a single ejector is additionally accelerated by which snagging of the injection moulded part is avoided. The injection pressure is absorbed by the ejector base plate thus the ejection accelerator does not bear any load and has a longer service life. Due to the small component size a flexible positioning of the ejector accelerator in the ejector set is also possible when retrofitting.

25.10.2016 Meusburger launches new consumables for the food processing industry

The standard parts manufacturer Meusburger offers selected consumables with H1-food-safe approval. The high-quality products are therefore especially suitable for the food processing industry. In this sector all substances such as grease, oil, compounds or anticorrosives are subject to high standards so they must be selected with particular care. New in the Meusburger range are for example the VGI 250 S Lubricant and release agent and the VPG 70 FD Food-safe anti-corrosive.

11.10.2016 NEW – Meusburger cutting punches with configurable bases

04.10.2016 NEW from Meusburger – Compact slide units for smallest installation spaces

With the new compact slide units Meusburger offers a slim slide option especially for small installation spaces. In addition to their size the ready-to-use versions also convince by their quality. High wear resistance and best sliding properties are possible through the DLC coated slides. Furthermore highest precision in the design and the production of the new slide units guarantee maximum process reliability in the injection moulding process.

01.10.2016 Outsourcing Instead of Self Made – Efficiency in Machine and Jig construction

Since the introduction of the area of business 'Jigs and Fixtures' the standard parts manufacturer Meusburger has recorded a steady growth in customer clientèle who build on the quality and the reliability of immediately available standard components. The trend towards standardisation is taking more and more hold in machine and jig construction. A logical development, considering that increasingly shorter project lead times and efficiency improvements are required in order to survive on the international market with the progressing globalisation.

20.09.2016 New cutting tools at Meusburger: indexable insert tools

30.08.2016 Meusburger offers a comprehensive range of accessories for spring installation

In die making, springs are an essential part to every die set. As a competent partner for die makers Meusburger offers, in addition to springs with round or rectangular cross section and elastomer compression springs in diverse shore hardness, also the most extensive range of accessories for spring installation on the market.

23.08.2016 NEW from Meusburger – Ejectors for longer service life

The new HSS ejector pins and DLC coated blade ejector pins with extra long blade from Meusburger guarantee long life and minimal wear. The use of high-speed steel and diamond-like carbon coating results in longer maintenance intervals and reduced downtimes. The two high-quality ejectors are as usual with Meusburger, available from stock.

18.08.2016 Safety first! New product group 'Protective equipment' at Meusburger

The theme protective equipment accompanies die and mould makers in their daily working life. To function as a competent full-range supplier, Meusburger expands its range in the area of workshop equipment with the new product group protective equipment. The standard parts manufacturer exclusively relies on the high-quality products from UVEX. The pre-sorted product range enables an easy and time-saving selection of the required protective equipment and as always with Meusburger, is available from stock.

04.08.2016 Meusburger standard components for the modular concept

Meusburger's convenient and cost-effective standard components guarantee an easy installation of die modules. Key advantages when using modules are quick tool changes and therefore reduced downtimes. The Austrian standard parts manufacturer offers users the possibility to use these advantages with its extensive range of products for the modular concept.

21.07.2016 NEW from Meusburger – Automatic safety hose coupler for cooling circuit connections

An innovative solution in the area of temperature regulation components assures more safety at work. Risk of scalding starts at a water temperature of 55°C, therefore an unintentional decoupling of the temperature regulation components can have fatal consequences. The new automatic safety hose coupler can prevent such accidents.

28.06.2016 Meusburger sets standards at the wfb

From 7th until 8th of June the wfb trade fair for die and mould making took place in Augsburg. Also this year, the standard parts manufacturer Meusburger was represented with a stand. In addition to the standard components, it presented current new products. An active exchange took place not only at the stand, but also in the newly introduced campfire sessions. For the first time, the wfb offered to the visitors the opportunity to exchange information about specialised topics in small discussion groups.

15.06.2016 NEW from Meusburger – In-house manufactured cutting punches with round base

The standard parts manufacturer responds to customer requests and now offers a wide range of cutting punches with round bases. These are manufactured in-house within a short time span with the new automated cylindrical grinding machine. Therefore Meusburger can guarantee especially attractive lead times.

31.05.2016 NEW in range from Meusburger – SD- and SZ-Two-pillar die sets

With the new two-pillar die sets, in which the guide pillars are arranged diagonally or centrally, Meusburger enables its customers new and flexible applications. The optimised arrangement of the retainer clip for the pillars and bushes retainer guarantees the SZ Two-pillar die set, central guiding a maximum usable width. The SD Two-pillar die set, diagonal guiding is designed for use in the length and width.

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]