Contatto

Siamo a vostra disposizione da lunedì a venerdì dalle ore 8:00 alle ore 17:00. In questo link troverete le persone di contatto per la vostra regione.

Sede di Wolfurt

+43 5574 6706-0

Carrello acquisti {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Articoli Cambia carrello acquisti

Nota

| Foto | Articoli | Pz. | Prezzo singolo | Prezzo unitario | Prezzo unitario incluso lo sconto | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Clienti

- Costruzione stampi

- Stampi per tranciatura

- Costruzione macchine e dispositivi

- Progettisti

- Stampaggio ad iniezione

-

Prodotti

- Nuovi prodotti

- Portastampi

-

Basi portastampo

- La base portastampo standard SV

- Basi portastampo di precisione SP

- Base portastampo a due colonne con guida posteriore SH

- Base portastampo diagonale a due colonne SD

- Base portastampo centrale a due colonne SZ

- Tecnica modulare SM

- BASI PORTASTAMPO TRANCIA-PIEGATRICI SB

- Sistema di staffaggio H 3000

- Piastre P

- Barre N

- Piastre e barre

- Lavorazioni speciali

- Accessori E

- Tecnica del canale caldo

- Termoregolazione canale caldo

- Prodotti per l‘officina

- Azienda

- Carriera

- Servizio clienti

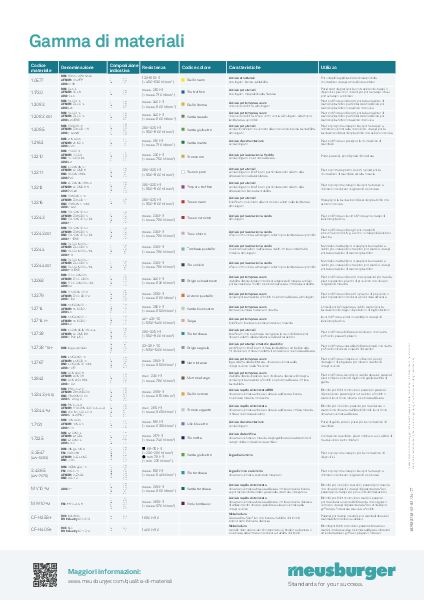

La nostra vasta gamma permette di trovare il materiale idoneo per quasi tutte le applicazioni.

1.2714 Steel for through hardening

Designation

| DIN: | 55 NiCrMoV 7 |

| AFNOR: | 55 NCDV 7 |

| UNI: | - |

| AISI: | L6 |

Chemical composition:

| C | 0.56 |

| Cr | 1.10 |

| Mo | 0.50 |

| Ni | 1.70 |

| V | 0.10 |

Strength:

max. 250 HB

(≈ max. 850 N/mm²)

Thermal conductivity at 100 °C:

36 W/m K

Character:

steel for through hardening, with high temperature resistance, through hardenability and toughness

Application:

extrusion dies, hot-forging tools, dies for processing tin, lead and zinc alloys

Treatment by

Polishing:

technical polishing is possible

is possible:

EDM, nitriding, etching and hard chroming

Heat treatment:

Soft annealing:

650 to 700 °C for about 4 to 5 hours; slow controlled cooling of 10 to 20 °C per hour to about 600 °C; further cooling in air, max. 248 HB

Hardening:

950 to 980 °C

15 to 30 minutes keeping curing temperature

quenching in water/oil

obtainable hardness: 56 HRC

Tempering:

slow heating to tempering temperature immediately after hardening; minimum time in furnace: 1 hour per 20 mm part thickness

Vai alla panoramica per la costruzione stampi Vai alla panoramica per la costruzione stampi per tranciatura

Available in the web shop as:

Data sheet 1.2714

Azienda

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Standard bars

Standard bars NR-Round bars

NR-Round bars

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]