Contact

We are gladly available for you from Monday to Friday from 8:00 to 17:00. Use this link to find the contact persons for your region.

Headquarters Wolfurt

+43 5574 6706-0

Shopping cart {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Items Change shopping cart

Remark

| Picture | Items | Pcs | Single price | Total price | Total price incl. discount | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Customers

- Mould making

- Die making

- Jigs and fixtures

- Area for designers

- Injection moulders

- Products

- Company

- Job opportunities

- Service

Are you interested in our company and our products? Then you’re in the right place.

Press releases

In this section you will find press releases regarding our company and new products, as well as your contact for press enquiries.

All

06.08.2024 Guiding systems for die making

The guiding system is one of the most important components of a properly functioning die set. Meusburger offers a comprehensive, interchangeable range of bearing and sliding guides for a wide variety of applications. There are numerous combination options between guide pillars and guide bushes. The guides are also compatible according to DIN/ISO and optimally matched to the standardised Meusburger die sets.

14.06.2024 Durable and precise – ejector set guiding from Meusburger

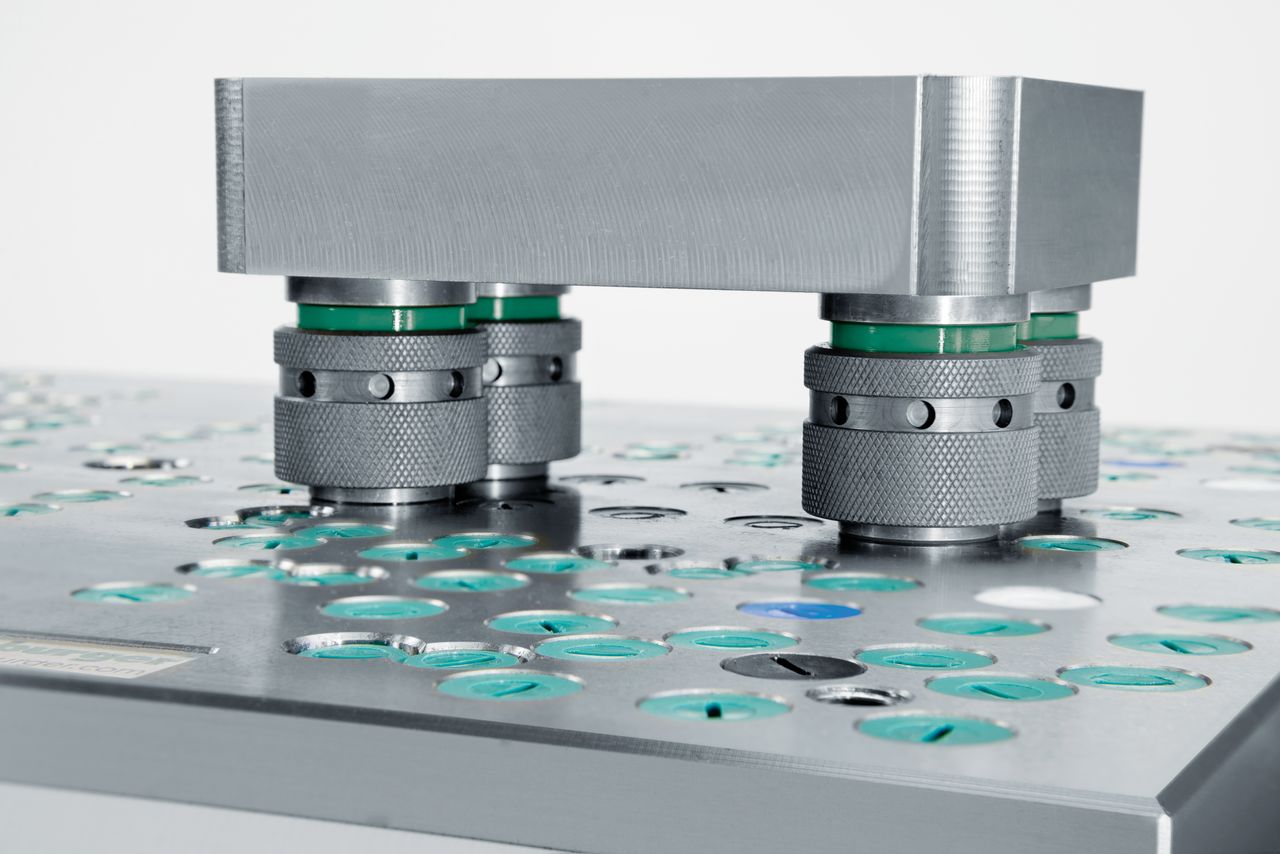

25.04.2024 The multifunctional clamping system for mould making

12.03.2024 The right material for every requirement in die making

To meet the different requirements for cutting steels used in die making, Meusburger has a large selection of eroding blocks that cover a wide range of materials, including classic steel for through hardening, high-speed steel, powder metallurgical steel and carbide. The eroding blocks are mainly used for the production of cutting punches and die plates and are available from stock in heat-treated and hardened versions. Their thicknesses are perfectly matched to the plates of Meusburger's standardised die sets and to the standardised lengths of the punches.

22.02.2024 Successful work with Meusburger plates

Looking for high-quality plates? As standard parts manufacturer, Meusburger can provide the best possible support in this regard. With over 30 material grades stored on an area of 2.5 football fields and a high-percentage of in-house production, the best quality as well as process reliability and supply security are guaranteed.

06.02.2024 Maximum efficiency through standardisation of die sets

22.01.2024 Meusburger focuses on its core competences

Despite the demanding market conditions, the company is successfully overcoming the challenges and continuing to invest in order to offer its customers the best service and the highest quality. This year, the standard parts manufacturer will continue to focus on further optimising its core competencies in the area of plates and components to expand its position as market leader. Last year, the company was already able to support its customers as a reliable supplier thanks to its central location in the heart of Europe and its extensive standard parts warehouse. In 2023, Meusburger generated a turnover of 327 million euros.

12.01.2024 Single nozzle easyFILL EH 4010

28.11.2023 Configure cutting bushes quickly and easily

10.10.2023 Welcome to the next level – Check out the new Meusburger portal now

After preparing intensively, it is finally time – the new Meusburger portal runs parallel to the previous version. The standard parts manufacturer has taken its online world to a new level so that its customers can reach their goal as quickly and intuitively as possible. With just a few clicks, the portal is easy to use for any target group. That’s not it, Meusburger is constantly further developing its portal and even more functions will be available in the future. The advantages that the new portal already offers are summed up below.

29.08.2023 Meusburger presents range at Fakuma

It’s time again – the international trade fair for plastics processing will take place in Friedrichshafen from 17 to 21 October. Meusburger will be attending and showcasing its product range at stands 2313 and 2316 in hall A2. Alongside its range for injection moulders, the wide range of components and the ENGEL injection moulding machine, the spotlight will be on the company’s latest campaign relating to bars.

22.06.2023 Custom-made components

23.05.2023 Optimised set-up time thanks to multi coupler

Often there are long set-up times and unnecessary machine downtimes due to numerous temperature regulation connections. Not only time loss but also quality issues can also result through possible coupling errors. Meusburger offers the perfect solution for optimising set-up times with their system EU and USA multi couplers.

20.04.2023 Meusburger at the Moulding Expo with a new campaign

The Moulding Expo, the most important European event for the mould and die making industry, will take place in Stuttgart from 13 to 16 June 2023. Of course, Meusburger will be there again. In addition to its new products and a comprehensive range for injection moulders, the standard parts manufacturer will be presenting its latest campaign on cavities. Visitors will also be able to find out about standardised and customised solutions for hot runner systems. At the Meusburger stand E41 in hall 1, guests can even watch lunch boxes be produced live on an injection moulding machine from ENGEL.

13.04.2023 Our heart beats for your cavity

At Meusburger you benefit from high-precision components to suit your requirements. As part of the latest campaign from the standard parts manufacturer, find out about the different products available in the range for cavities and why Meusburger can provide you with the best advice. The company has packaged the core message "Our heart beats for your cavity" in two creative videos.

07.03.2023 Higher quality thanks to the cooled compact slide unit

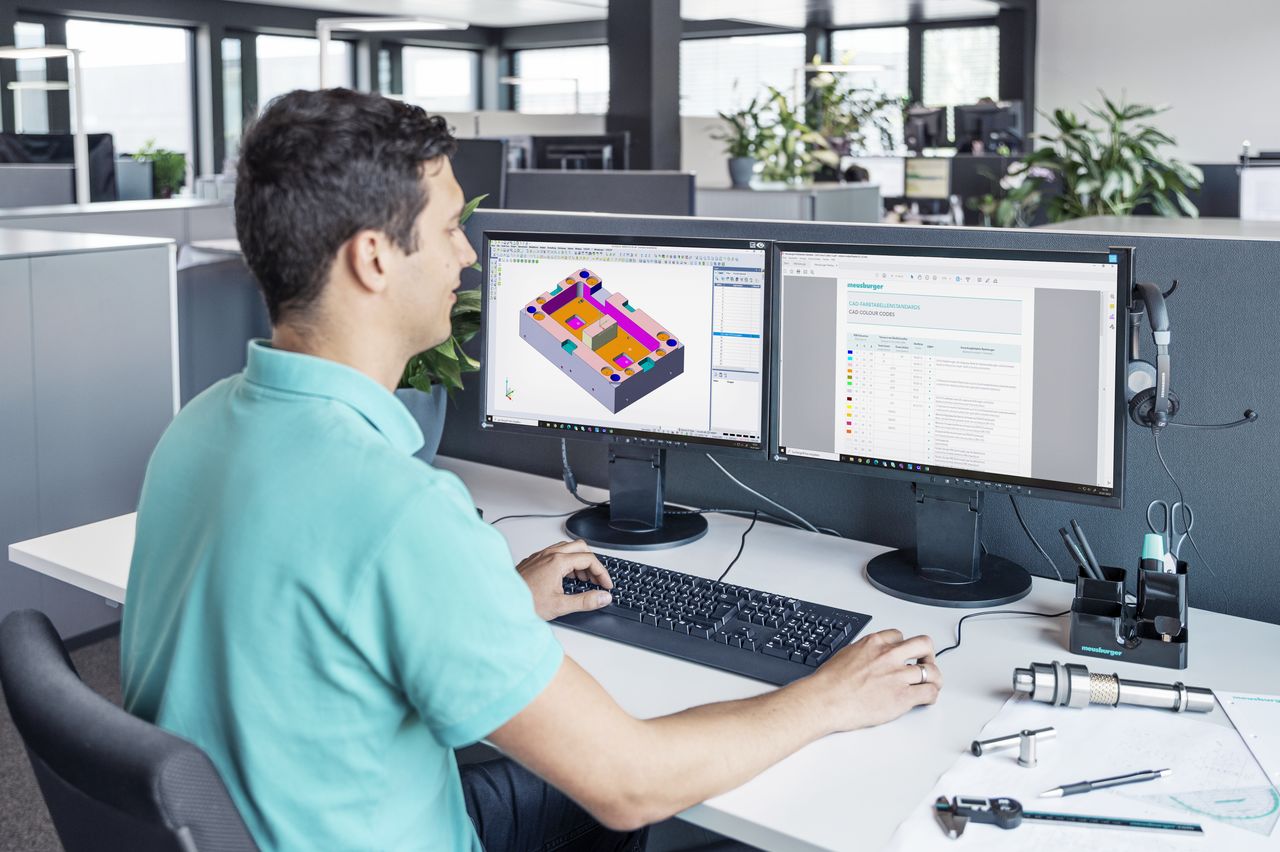

16.02.2023 Easy to design thanks to the Meusburger colour codes

24.01.2023 Meusburger keeps getting stronger

After a turbulent year in 2022, Meusburger continues to be a reliable supplier in the mould and die making industry. Despite the challenges in the past year, the standard parts manufacturer has optimised existing processes and further advanced digitalisation. The company recorded a 16% growth in turnover, partly due to increased costs and resulting price increases.

13.01.2023 Precise temperature control with the profiTEMP IM

01.12.2022 The ideal basis for durable injection moulds

11.11.2022 The ideal basis for your injection moulding solution

Whether standard moulds, sliding core moulds, change moulds or micro moulds – Meusburger offers a comprehensive range of products. Customers benefit not only from many years of experience, but also from production from high-grade steel, heat-treated for stress relief, as well as from fast order processing from request to delivery. As usual, all mould bases are available from stock. The standard parts manufacturer’s latest campaign consists of three statements combined with short videos and tells you exactly what makes the mould bases so unique.

04.08.2022 Meusburger presents product range at K 2022

At this year’s K trade fair in Düsseldorf from 19 to 26 October, Meusburger will focus on its standardised mould bases. The standard parts manufacturer will also present its range for injection moulders and both the standardised and the customised solutions for hot runner systems. A special highlight of stand C30 in hall 1 will be the ENGEL injection moulding machine, where visitors can watch a bread box being produced.

28.07.2022 Standardised components for strip guiding

Many stamping die components such as strip guiding are usually produced in small quantities, which is quite expensive and time-consuming. That is why using standardised components is a good option. Advantages include immediate availability, the combination possibilities of the different types of strip guiding within the stamping die, and the provided CAD data for the design. The following takes a closer look at the strip guiding solutions available at Meusburger.

28.04.2022 Professional diagnosis with the profiTEMP TM

10.02.2022 Extensive range of springs at Meusburger

04.02.2022 Meusburger is ready for the future

2021 was complicated by both supply shortages and rising commodity prices, as well as limited customer visits due to the Covid situation. Despite these challenges, Meusburger was able to guarantee its customers continuous service and constant delivery availability. Thus, the standard parts manufacturer from Austria was able to achieve a turnover of 302 million euros thanks to the large warehouse and the high proportion of in-house production.

21.01.2022 Maximum closing force with the powerMOVE

The powerMOVE lever operated lifting plate is an integral part of the hot half in our range of valve gate systems. Matched to the sizes in the plates range, various standardised powerMOVE units are available, which are customised according to the individual requirements. The arrangement of the nozzles can be freely configured.

11.01.2022 Innovations in workshop equipment from Meusburger

11.11.2021 Meusburger guarantees supply security despite the crisis

22.10.2021 Meusburger highlights at Fakuma

From the 12–16 October Meusburger was represented at Fakuma, the international trade fair for plastics processing in Friedrichshafen, Germany. The range for injection moulders as well as the standard and custom hot runner systems were in the spotlight. The visitors in hall A2 at stand 2313 and 2317 also got the first look at Meusburger’s brand new trade fair stand design. Another particular highlight at the stand was the Engel injection moulding machine, which visitors were able to watch live in action producing bread boxes.

21.09.2021 Low-leakage couplers – for flawless and reliable temperature regulation in cleanrooms

15.07.2021 The right spring for your project

Meusburger’s extensive range of springs offers you the right spring for every situation - from very low to extremely high loads. To make the design process as simple as possible, Meusburger created a wizard for selecting the right system compression spring at the beginning of the year. Intuitively designed and easy to use, the wizard helps you select the right spring with just a few clicks. The configurable data is then available for download.

29.06.2021 Optimal gate temperature control made easy

01.06.2021 Meusburger guarantees continuous delivery availability even during the raw material crisis

The current sharp increase of raw material prices is causing uncertainty for many companies. The dramatic rise in costs is due to the increasing demand for steel which has resulted in a global steel shortage. This has caused not only supply bottlenecks but an extreme increase in prices. For example, the price for steel grade 1.1730 has doubled. From today’s perspective, it is unclear when the situation will ease again.

22.04.2021 Reliable and environmentally friendly sealing

30.03.2021 Standardisation in the hot runner sector with the FH mould

In today’s world, standardisation plays a major role for successfully operating a company in most industries. This also applies for the hot runner sector where substantial time and savings potentials are possible through standardisation. The FH hot runner mould from Meusburger is the perfect example. It consists of a complete mould base including a hot runner system.

23.02.2021 10 years of standardisation in die making

14.01.2021 Innovative solution for optimal slide retention

Slide retainers are needed to hold slides securely in the end position when the mould is open. With the new E 3050 leaf spring roll stopper, Meusburger has created an exclusive and cost-effective alternative to existing solutions on the market. The compact design enables retaining forces of up to 140 N and is therefore also ideal for holding large slide bodies in their end position. In order to cover a wide range of applications, the leaf spring roll stopper is available in two different variations and three different leaf spring thicknesses.

10.12.2020 The right plate for every project

29.10.2020 New workshop equipment products from Meusburger

In order to meet customers’ needs, the product range at Meusburger is constantly being expanded - like our workshop equipment range in mid-October. New innovations have been added to the product groups surface finishing equipment, assembly equipment and clamping equipment, and there were expansions in the areas of cutting tools and EDM accessories.

16.10.2020 Save time and money with the new clamping configurator

According to a study, a mould making company spends an average of 600 hours per year on machine setup. This time can be significantly reduced by using a zero clamping system. As renowned plate supplier, Meusburger offers an additional service for this. Now customers can order the plates they need to machine with the fitting holes for the clamping bolts of their zero clamping system. This new service will make the value chain for plate machining even more efficient.

22.09.2020 Meusburger provides tried and trusted CAD tool free of charge

Together with their customer Schmidt WFT, Meusburger has developed a CAD tool that is now available to you free of charge. This tried and trusted tool is coordinated with the Siemens NX CAD system and enables designers to carry out a simple and time-saving design process. Configurations of components which are native in the system can be selected and all parameters are automatically adjusted. Installation spaces and the colour table standards developed by Meusburger together with the Association of German Tool and Mould Makers are also integrated in the tool. The parts list is automatically updated when changes are made.

01.09.2020 Quick & easy to replace: the guide pillar with conical shank

24.07.2020 TT slide unit now available in two new sizes

In addition to the existing sizes with slide surfaces of 12 x 10 mm and 15 x 12 mm, the tried and trusted E 3310 TT slide unit from Meusburger has been expanded with two new sizes with slide surfaces of 8 x 6 mm and 18 x 14 mm. The ready-to-use slide unit reduces overall costs during design and mould manufacturing. In addition, daily work is facilitated through the compatibility of the components and the direct download of CAD data including installation spaces. Small slide units are in particular demand for complex moulds.

07.07.2020 Coatings increase the service life of cutting punches

The abrasive and adhesive wear that occurs during the stamping process on the cutting punch is minimised by coatings. This leads to a significant increase in the service life of cutting punches and consequently also reduces machine downtimes. In addition, the retracting forces are reduced due to the lower coefficient of friction. Different coatings are used depending on the materials to be punched. We give you an overview of the common coatings with their respective properties and application areas.

25.06.2020 Build-in cylinder with flange – new diameter available from stock

Meusburger offers the compact build-in cylinder with flange ideal for the smallest installation spaces. Thanks to uncomplicated incorporation and the supplied screws, it can be installed in no time at all. In addition, the two-step installation hole protects the sealing during installation. New in range is the build-in cylinder with flange with a piston diameter of 20 mm.

04.06.2020 Sintered iron in die making – the strong alternative

In addition to the classic materials for sliding guides such as steel and bronze, sintered iron has long been regarded as a strong alternative in die making. Thanks to its porosity, it is ideally suited for use as a slide bearing. It also offers high wear resistance and has very good emergency operating features.

15.05.2020 Cavity pressure sensors: single wire vs. coaxial

The cavity pressure is an important parameter in process monitoring during plastic injection moulding. Pressure sensors are therefore indispensable for comprehensive mould monitoring. The use of high-quality piezoelectric sensors leads to optimal process quality and increases part quality sustainably. Two different technologies are available on the market for charge transfer: single wire and coaxial cables. We will show you the essential differences and characteristics of these two variants.

30.04.2020 Meusburger premium power clamps for injection moulding

17.04.2020 Material grade 1.2738 TSHH now available from stock

Reducing processing time and optimising costs is especially important for injection moulds with moderate shot weights. In addition, flawless surface quality is often required for injection moulded parts. 1.2738 TSHH steel has long been established on the market for this purpose. This steel is especially useful in the automotive industry, but also for consumer goods. Meusburger now offers cavity plates and standard plates in the material grade 1.2738 TSHH available from stock.

07.04.2020 The right material for every requirement in die making

To meet the different requirements for cutting steels used in die making, Meusburger has a large selection of NE blocks for eroding that cover a wide range of materials - including classic steel for through hardening, high-speed steel, powder metallurgical steel and carbide. The blocks for eroding are mainly used for the production of cutting punches and dies and are available from stock in heat-treated and hardened versions. Their thicknesses are perfectly matched to the plates of Meusburger’s standardised die sets.

10.04.2020 Position sensing for high process reliability

Position sensing plays an important role in a reliable injection moulding process. Whether for monitoring the end positions of a slide, ejector set or hydraulic cylinder – mechanical and inductive sensors have become essential in modern mould and die making. Here is an overview of the most common variations for position control of components in the mould.

06.02.2020 Top reliability when operating 3-plate moulds

Latch locks are used to control moulds with 2 split lines, often referred to as 3-plate moulds. With the new E 1817 latch lock, Meusburger has created an exclusive and cost-effective alternative to existing products on the market, such as round or flat latch locks. Thanks to its simple mechanical functional principle, the new latch lock offers maximum reliability in the control of 3-plate moulds. In addition, it features a compact design as well as low machining effort prior to its installation.

30.01.2020 Milling cutters especially for hard machining from Meusburger

Meusburger offers the optimal solutions for machining hardened material up to 67 HRC. The hard milling cutters in different variations achieve highest precision and quality. Most milling cutters are used in Meusburger’s own production. This means that the range is perfectly matched to the requirements and materials in mould and die making.

29.10.2019 Market innovations presented by Meusburger at the K trade fair

At this year’s K trade fair in Düsseldorf, the Meusburger stand featured the new configurator for hot runner moulds. The new cavity pressure sensors and many other Meusburger products were also presented to visitors, alongside the unmissable hot runner and control systems, WBI Knowledge Management and ERP software.

17.10.2019 Meusburger joins forces in 2020

24.09.2019 Meusburger presents their brand new stamping and forming die set at the Blechexpo 2019

20.08.2019 Meusburger at the K 2019 with market innovations

At this year’s K trade fair in Düsseldorf (16 to 23 October), the Meusburger stand (hall 1, stand C30) will feature the new and one-of-a-kind configurator for hot runner moulds. In addition, the new cavity pressure sensors and many other Meusburger products will be presented. Of course the divisions of hot runner and control systems, Knowledge Management, and ERP will also be presented.

13.08.2019 A new generation of ejectors for inclined ejection units

For easier demoulding of internal undercuts in plastic parts, ejectors for inclined ejection units can often be used instead of slide units. With the new E 3270 Inclined ejection unit, Meusburger offers a cost-effective and ready-to-use alternative to the existing ejectors for inclined ejection units on the market. The part geometry is created with a block for eroding which allows for maximum design flexibility. The DLC coating of the ejector rod ensures minimal wear, best sliding properties and ultimately a long service life.

23.07.2019 Optimal materials for machining

16.07.2019 Meusburger presents innovations in the field of workshop equipment

25.06.2019 Standardised stamping and forming die sets for Bihler presses

A brand-new market innovation is now available from Austrian standard parts manufacturer Meusburger and German stamping and forming machine specialist Bihler. In a close cooperation between the two companies, the first standardised stamping and forming die sets were developed with Meusburger standard parts for Bihler NC presses. The new die sets in types ‘tunnel cut’ or ‘spring-loaded guiding plate’ are available for stamping presses with forces up to 400kN and promise to bring enormous savings in time and cost for Meusburger and Bihler customers in future.

18.06.2019 Cavity pressure measurement for increased process efficiency in injection moulding

According to the motto ‘everything from one source’, in addition to standard parts for temperature and end position control, Meusburger now also offers sensors for cavity pressure measurement. With the matching connecting cable, these are compatible with all systems for analysis currently available on the market. The range includes two types each for direct and indirect measurement as well as suitable mounting accessories and connection cables - as usual available from stock with simple CAD data download from the Meusburger web shop.

21.05.2019 A comparison of different punch attachment options

Meusburger’s comprehensive range of standard parts offers a variety of possibilities for attaching punches - with direct CAD data export and available from stock for fast design and production. Depending on the application and conditions, cutting punches can be mounted or attached differently in the die set. This article takes a closer look at the different types of punch attachments, including the ball-lock system.

23.04.2019 Offset cutting punches at Meusburger

With the offset cutting punches from Meusburger there are many possibilities to configure the contour of cutting punches individually according to your needs. In addition, different materials and head shapes as well as coatings are available. These can be selected quickly and easily using the cutting punches configurator. Thanks to in-house production, Meusburger offers maximum precision and short lead times.

02.04.2019 A hot runner mould in just five minutes: with Meusburger, you can!

With the brand new Meusburger configurator for hot runner moulds a complete mould base including hot runner manifold can be customised with just a few clicks. The configurator offers highest flexibility, immediate creation of the 3D data and immediate price display. This world first on the market is the result of the very good cooperation between Meusburger and PSG.

26.03.2019 The Meusburger Group at Moulding Expo 2019

At this year’s Moulding Expo in Stuttgart (21–24 May), the Meusburger Group’s stand (hall 7, stand C17) will feature the brand new and one-of-a-kind configurator for hot runner moulds. In addition, the new cavity pressure sensors and many other Meusburger products will be presented. The companies PSG, WBI and Segoni will also offer a glimpse into their product range.

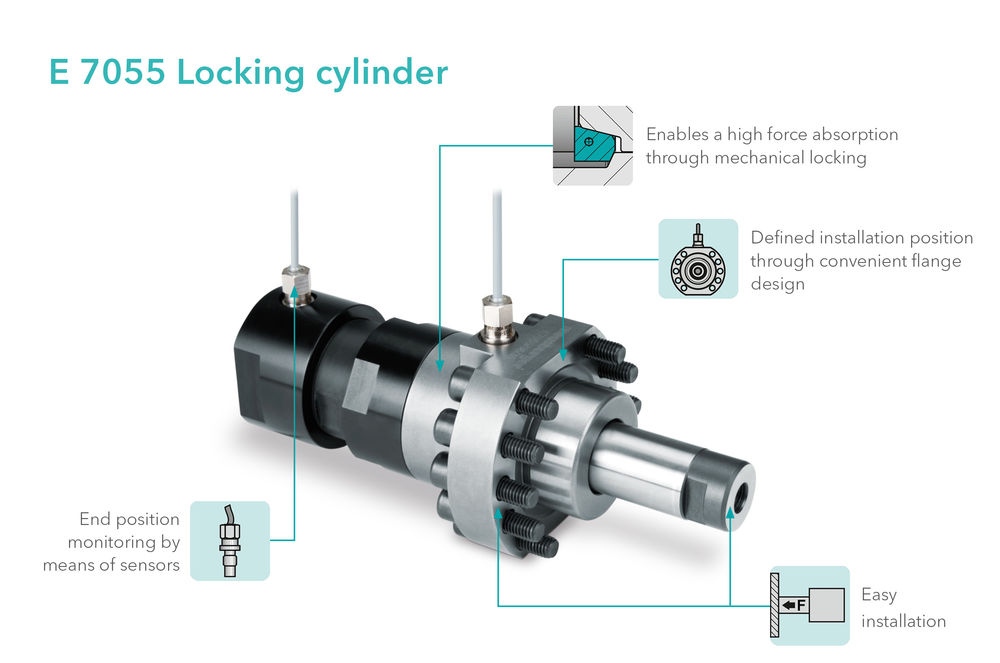

16.03.2019 Compact design with the Meusburger locking cylinder

26.02.2019 New embossing elements for die making

22.01.2019 Exclusively at Meusburger: DLC coated flat guiding stock

18.12.2018 Tried and trusted components now available in stainless steel

Stainless steel components are mainly used in processing corrosive plastics or in clean room technology (e.g. medical or food processing applications). Meusburger has expanded its product range especially in the temperature regulation components, ejectors, and demoulding product groups with numerous new stainless steel components.

05.12.2018 Successful standardisation begins in the design phase

Die Welt wächst zusammen – logistisch und wirtschaftlich. Die Globalisierung erhöht für den Werkzeug- und Formenbau den Wettbewerbsdruck, bietet aber auch die Chance, von Aufträgen in schnell wachsenden Märkten zu profitieren. Gleichzeitig dreht sich die Innovationsspirale immer schneller, was von den Unternehmen Anpassungsfähigkeit und Flexibilität abverlangt. Der hohe Kosten- und Zeitdruck zwingt die Betriebe somit zu einer ständigen Effizienzsteigerung. Ein hoher Grad an Standardisierung über die gesamte Prozesskette bietet hier eine ausgezeichnete Möglichkeit, um Kosten und die Durchlaufzeit von Projekten drastisch zu senken.

15.11.2018 5,000 new plates and bars sizes

09.10.2018 NEW from Meusburger: Blocks for eroding with starting hole

27.09.2018 Proper heat treatment paves the way to success

Not all stress-relieving heat treatment is the same – because only a proper heat treatment process ensures the desired result in the end. That is why Meusburger has been using its own furnaces for almost 30 years. Meusburger stands for top-quality products – only flawless steel from the best-known steelworks can make it through the quality check. Standard parts that are heat-treated for stress relief are right at the beginning of the die and mould making process chain and form the basis of high-quality moulds and dies.

13.09.2018 Leakage problems at high temperatures?

Increasing with high temperatures, leakage problems can occur at various points. Sooner or later, the typical brass plugs can lead to leaks – this results in machine downtimes and increased maintenance intervals. It is often assumed that the problem is the sealant used, but this is usually not the reason: Due to different coefficients of expansion of brass plugs and steel plates, setting occurs during heating and cooling of the mould which consequently leads to leakage.

04.09.2018 Meusburger enables universal die set monitoring

The logic distributors by Meusburger in combination with the new limit switches with roller or dome plunger enable universal die set monitoring. The sensors of the limit switches are able to collect signals from different installation positions due to the adjustable roller. The manifold combines several of these signals without voltage drop. Simple and quick installation with maximum flexibility is ensured by the compact design and the many plug-in options.

23.08.2018 The Meusburger Group is represented at the Fakuma 2018

From the 16th to the 20th of October 2018, the Meusburger Group will be represented at the international trade fair for the processing of plastics in hall A2 at stand 2313 and 2317. With the motto ‘everything from a single source’, Meusburger, PSG, WBI and the youngest group member, Segoni will present new and tried and trusted products and services in the field of mould and die making.

24.07.2018 Meusburger presents the smallest ready-to-use slide unit on the market

The new member of the Meusburger family of compact slide units is the E 3310 TT-Slide unit, which features a compact design. The ready-to-use slide unit reduces overall costs during design and tool manufacturing. In addition, daily work is facilitated through the compatibility of the components and the direct download of CAD data including installation spaces. Small slide units are in particular demand for complex moulds.

12.07.2018 E 5636 Strip guiding rail in lengths 60 and 100 mm

10.07.2018 Stamps with latching function for even higher process reliability

Marking stamps are used for clear marking of injection-moulded parts. To prevent unintended movement of the arrow insert, Meusburger now offers stamps with a latching function. These ensure even higher process reliability during the injection moulding process, and prevent parts being marked incorrectly.

05.07.2018 Meusburger Group takes over Segoni

Wolfurt/Austria. The internationally active Meusburger Group with headquarters in Wolfurt will be taking over Segoni. The Berlin software specialist will continue as an independent enterprise, and all employees will be retained. In the coming years, long-term investments will be made in the further development of the software. Alongside the knowledge-based management method WBI, customers of the Meusburger Group will also be supported in the area of ERP/PPS through the digitalisation process.

28.06.2018 New catalogue for machine and jig construction

The hot off the presses Meusburger catalogue ‘Machine and Jig Construction 2019/2020’ is now available with numerous innovations. Customers will find the expanded product range on over 400 pages with 37,000 items clearly presented. The standardised and quickly available plates and bars are available in 29 different materials. And there is also a completely new product group: the components, which are specially tailored to the requirements of jig construction.

21.06.2018 Meusburger presents innovations in the field of workshop equipment

05.06.2018 A must-have in modern die and mould making: DLC coated components

08.05.2018 Innovations for the modular concept

Meusburger presents exclusive and groundbreaking innovations for the modular concept at the Stanztec trade fair. The E 5076 and E 5078 Module guides are now available in configurable lengths. This offers the customer maximum flexibility during the design of die modules. The slide-in aid reduces the processing costs and set-up times to a minimum. With the modular design wizard, the time-consuming and difficult selection of individual plates is a thing of the past.

24.04.2018 NEW from Meusburger: E 7048 Build-in cylinder with flange

Ideal for the smallest installation spaces, Meusburger now exclusively offers the compact build-in cylinder with flange. Thanks to an uncomplicated incorporation and the supplied screws, it can be installed in no time at all. In addition, the two-step installation hole protects the sealing during installation.

22.03.2018 New cutting punches and contour bases at Meusburger

08.03.2018 The largest range of temperature regulation solutions for mould making

Meusburger is constantly expanding its range of temperature regulation solutions, which leads to a higher level of safety in operation as well as savings in time during the design and use. New in the range are temperature regulation components with sealant, plug-in type bridges and the Stäubli RMI Multi coupler system.

13.02.2018 Increased stamping process reliability with precision control devices

19.01.2018 High-quality steel for metalworking

06.12.2017 NEW from Meusburger: HFC rough milling cutters

The new high-feed milling cutters WZF 11512 and WZF 11522, or HFC milling cutters for short (HFC stands for High Feed Cutting), are mainly used for roughing. This procedure is particularly economical, as very high cutting speeds and feed rates can be reached. In addition, these milling cutters guarantee higher process reliability through a controlled wear process without cutting edge breakage.

21.11.2017 New from Meusburger: E 1307 Fine centring unit, flat for high-precision centring of inserts

The new E 1307 Fine centring unit, flat from Meusburger features minimal installation space which provides for maximum space utilisation within the insert. Through the DLC coated centring elements available with or without fixing holes the designer enjoys maximum flexibility during design, and the wear is reduced to a minimum.

24.10.2017 Die casting components for die and mould making

03.10.2017 Exclusive guide for inclined pin from Meusburger

The exclusive E 3064 Guide for inclined pin stands out due to optimal surface contact with the inclined pin and best material pairings. This results in a high force absorption. The machining of the pocket in the slide is possible without inclining. In addition the slide stroke can be adjusted subsequently by customising, or adjusting the position of the guide for inclined pin.

19.09.2017 Meusburger expands its range in the area of gas springs

04.09.2017 Merger of Meusburger and PSG China

29.08.2017 The Meusburger highlights at the Fakuma 2017

From the 17th to the 21st of October, Meusburger presents both the tried and trusted products and numerous innovations at the international trade fair for the processing of plastics. The precision cutting and grinding machine, the gear unit for stack moulds, and the high temperature hose are just a few of the product highlights that can be seen at the Meusburger stand no. 2313 in hall A2.

16.08.2017 Meusburger sets standards with the smartFILL single nozzles from PSG

The expert in standard components Meusburger now has the smartFILL single nozzles from PSG in range. Best part quality and a wide range of applications make the smartFILL hot runner single nozzle the poster child of PSG. By using this nozzle the melt is tempered homogeneously to the injected part guaranteeing highest quality of parts. With the easily interchangeable nozzle tips, different types of gating are possible which makes the smartFILL nozzles suitable for a wide range of applications and all common thermoplastics with and without fillers.

01.08.2017 Efficiency in machine and jig construction Meusburger at EMO 2017

From September 18th to 23rd 2017, EMO, the trade fair for metalworking, opens its doors in Hannover. Meusburger will also be represented this year in Hall 5 at Stand E 24 and informing visitors about its wide range of products as well as the advantages of standardisation in machine and jig construction.

18.07.2017 Meusburger now offers new guiding elements in the area of die making

04.07.2017 More safety in the operation thanks to the IsoTemp® high temperature hose

The new E 2187 IsoTemp® high temperature hoses from Meusburger combine tried and trusted technology with an innovative silicone sheath. This offers protection against burns as well as against abrasion or damages to the metal sheath. Therefore there is no risk of injuries from protruding wires. The special construction provides for high durability and maximum flexibility.

20.06.2017 Clamping devices for ergonomic work during polishing

Ergonomics plays a central role in the design of a safe and healthy working environment in many areas. With the new tiltable tables and magnetic clamping balls, which enable ergonomic work during polishing, the standard parts manufacturer expands its workshop equipment range and makes an important contribution for modern workplace design.

23.05.2017 Meusburger expands its range in the area of active parts

The standard parts manufacturer Meusburger now offers three new, innovative components in the area of active parts: a punch suspension piece with radius for fixing and installation of filigree punches, a block-shaped strip lifter with large contact surface and an additional size for the tried and trusted infeed guide for strip widths up to 152 mm.

09.05.2017 Double output thanks to the new Meusburger gear unit for stack moulds

25.04.2017 New configuration options for Meusburger cutting punches

The standard parts manufacturer Meusburger now offers new configuration options for cutting punches. This includes two different PVD coatings for maximum service life and the configuration of anti-rotation protection for shape punches. The cutting punches can be quickly and easily selected via the new configurator in the Meusburger digital catalogues.

28.03.2017 NEW from Meusburger: tunnel gate inserts for large contour steps

15.03.2017 Achieve maximum precision with the Meusburger guide pillar with centre collar

28.02.2017 NEW from Meusburger: magnetic proximity sensor and magnetic cable retainer

The standard parts manufacturer Meusburger expands its product range in the area of electrical components. The E 65620 Magnetic proximity sensor for T-slots with reliable and precise switching point is ideally suited for use as a cylinder sensor. For easy and secure fixing of cables within the moulds, Meusburger now also offers the universally usable E 2766 Magnetic cable retainer.

14.02.2017 Reliable clamping with Meusburger high-pressure clamping equipment

The standard parts manufacturer Meusburger expands its range of workshop equipment especially coordinated to die and mould making with high-quality high-pressure clamping equipment. In addition to the tried and trusted centring vices Meusburger now offers high-pressure vices in three different variations. Due to the integrated power amplifier a clamping force of up to 50 kN is reached. The repeatable accuracy during clamping is 0.01 and enables highest precision in the machining of workpieces.

18.01.2017 Meusburger hydraulic cylinders now with stroke of up to 200 mm

From now on the standard parts manufacturer Meusburger also offers hydraulic cylinders with a stroke of up to 200 mm available from stock. Thanks to the finely graduated stroke lengths a large application range is possible. Due to the standard lengths and transverse holes the double-acting cylinders can be flexibly installed.

03.01.2017 NEW from Meusburger - Adjustment unit with even more precise positioning

20.12.2016 Tried and trusted latch locks – now with DLC coating

06.12.2016 NEW at Meusburger – Compact and ready-to-use pilot unit

23.11.2016 NEW from Meusburger: flat-face centring unit with round fitting

Since October Meusburger offers a flat-face centring unit with round fitting. This innovative product in the range of Meusburger locks offers an additional option for a reliable and exact final centring of the mould at the split line face. Due to its geometry the new centring unit is optimal for moulds with unequal thermal expansion.

15.11.2016 NEW from Meusburger – carbide blocks for eroding

08.11.2016 Reliable demoulding of complex injection moulded parts

The compact ejector accelerator from Meusburger is the ideal device for the safe and targeted ejection of complex parts: a single ejector is additionally accelerated by which snagging of the injection moulded part is avoided. The injection pressure is absorbed by the ejector base plate thus the ejection accelerator does not bear any load and has a longer service life. Due to the small component size a flexible positioning of the ejector accelerator in the ejector set is also possible when retrofitting.

25.10.2016 Meusburger launches new consumables for the food processing industry

The standard parts manufacturer Meusburger offers selected consumables with H1-food-safe approval. The high-quality products are therefore especially suitable for the food processing industry. In this sector all substances such as grease, oil, compounds or anticorrosives are subject to high standards so they must be selected with particular care. New in the Meusburger range are for example the VGI 250 S Lubricant and release agent and the VPG 70 FD Food-safe anti-corrosive.

11.10.2016 NEW – Meusburger cutting punches with configurable bases

04.10.2016 NEW from Meusburger – Compact slide units for smallest installation spaces

With the new compact slide units Meusburger offers a slim slide option especially for small installation spaces. In addition to their size the ready-to-use versions also convince by their quality. High wear resistance and best sliding properties are possible through the DLC coated slides. Furthermore highest precision in the design and the production of the new slide units guarantee maximum process reliability in the injection moulding process.

01.10.2016 Outsourcing Instead of Self Made – Efficiency in Machine and Jig construction

Since the introduction of the area of business 'Jigs and Fixtures' the standard parts manufacturer Meusburger has recorded a steady growth in customer clientèle who build on the quality and the reliability of immediately available standard components. The trend towards standardisation is taking more and more hold in machine and jig construction. A logical development, considering that increasingly shorter project lead times and efficiency improvements are required in order to survive on the international market with the progressing globalisation.

20.09.2016 New cutting tools at Meusburger: indexable insert tools

30.08.2016 Meusburger offers a comprehensive range of accessories for spring installation

In die making, springs are an essential part to every die set. As a competent partner for die makers Meusburger offers, in addition to springs with round or rectangular cross section and elastomer compression springs in diverse shore hardness, also the most extensive range of accessories for spring installation on the market.

23.08.2016 NEW from Meusburger – Ejectors for longer service life

The new HSS ejector pins and DLC coated blade ejector pins with extra long blade from Meusburger guarantee long life and minimal wear. The use of high-speed steel and diamond-like carbon coating results in longer maintenance intervals and reduced downtimes. The two high-quality ejectors are as usual with Meusburger, available from stock.

18.08.2016 Safety first! New product group 'Protective equipment' at Meusburger

The theme protective equipment accompanies die and mould makers in their daily working life. To function as a competent full-range supplier, Meusburger expands its range in the area of workshop equipment with the new product group protective equipment. The standard parts manufacturer exclusively relies on the high-quality products from UVEX. The pre-sorted product range enables an easy and time-saving selection of the required protective equipment and as always with Meusburger, is available from stock.

04.08.2016 Meusburger standard components for the modular concept

Meusburger's convenient and cost-effective standard components guarantee an easy installation of die modules. Key advantages when using modules are quick tool changes and therefore reduced downtimes. The Austrian standard parts manufacturer offers users the possibility to use these advantages with its extensive range of products for the modular concept.

21.07.2016 NEW from Meusburger – Automatic safety hose coupler for cooling circuit connections

An innovative solution in the area of temperature regulation components assures more safety at work. Risk of scalding starts at a water temperature of 55°C, therefore an unintentional decoupling of the temperature regulation components can have fatal consequences. The new automatic safety hose coupler can prevent such accidents.

28.06.2016 Meusburger sets standards at the wfb

From 7th until 8th of June the wfb trade fair for die and mould making took place in Augsburg. Also this year, the standard parts manufacturer Meusburger was represented with a stand. In addition to the standard components, it presented current new products. An active exchange took place not only at the stand, but also in the newly introduced campfire sessions. For the first time, the wfb offered to the visitors the opportunity to exchange information about specialised topics in small discussion groups.

15.06.2016 NEW from Meusburger – In-house manufactured cutting punches with round base

The standard parts manufacturer responds to customer requests and now offers a wide range of cutting punches with round bases. These are manufactured in-house within a short time span with the new automated cylindrical grinding machine. Therefore Meusburger can guarantee especially attractive lead times.

31.05.2016 NEW in range from Meusburger – SD- and SZ-Two-pillar die sets

With the new two-pillar die sets, in which the guide pillars are arranged diagonally or centrally, Meusburger enables its customers new and flexible applications. The optimised arrangement of the retainer clip for the pillars and bushes retainer guarantees the SZ Two-pillar die set, central guiding a maximum usable width. The SD Two-pillar die set, diagonal guiding is designed for use in the length and width.

Die making

06.08.2024 Guiding systems for die making

The guiding system is one of the most important components of a properly functioning die set. Meusburger offers a comprehensive, interchangeable range of bearing and sliding guides for a wide variety of applications. There are numerous combination options between guide pillars and guide bushes. The guides are also compatible according to DIN/ISO and optimally matched to the standardised Meusburger die sets.

12.03.2024 The right material for every requirement in die making

To meet the different requirements for cutting steels used in die making, Meusburger has a large selection of eroding blocks that cover a wide range of materials, including classic steel for through hardening, high-speed steel, powder metallurgical steel and carbide. The eroding blocks are mainly used for the production of cutting punches and die plates and are available from stock in heat-treated and hardened versions. Their thicknesses are perfectly matched to the plates of Meusburger's standardised die sets and to the standardised lengths of the punches.

06.02.2024 Maximum efficiency through standardisation of die sets

28.11.2023 Configure cutting bushes quickly and easily

28.07.2022 Standardised components for strip guiding

Many stamping die components such as strip guiding are usually produced in small quantities, which is quite expensive and time-consuming. That is why using standardised components is a good option. Advantages include immediate availability, the combination possibilities of the different types of strip guiding within the stamping die, and the provided CAD data for the design. The following takes a closer look at the strip guiding solutions available at Meusburger.

10.02.2022 Extensive range of springs at Meusburger

11.01.2022 Innovations in workshop equipment from Meusburger

15.07.2021 The right spring for your project

Meusburger’s extensive range of springs offers you the right spring for every situation - from very low to extremely high loads. To make the design process as simple as possible, Meusburger created a wizard for selecting the right system compression spring at the beginning of the year. Intuitively designed and easy to use, the wizard helps you select the right spring with just a few clicks. The configurable data is then available for download.

23.02.2021 10 years of standardisation in die making

10.12.2020 The right plate for every project

29.10.2020 New workshop equipment products from Meusburger

In order to meet customers’ needs, the product range at Meusburger is constantly being expanded - like our workshop equipment range in mid-October. New innovations have been added to the product groups surface finishing equipment, assembly equipment and clamping equipment, and there were expansions in the areas of cutting tools and EDM accessories.

01.09.2020 Quick & easy to replace: the guide pillar with conical shank

07.07.2020 Coatings increase the service life of cutting punches

The abrasive and adhesive wear that occurs during the stamping process on the cutting punch is minimised by coatings. This leads to a significant increase in the service life of cutting punches and consequently also reduces machine downtimes. In addition, the retracting forces are reduced due to the lower coefficient of friction. Different coatings are used depending on the materials to be punched. We give you an overview of the common coatings with their respective properties and application areas.

04.06.2020 Sintered iron in die making – the strong alternative

In addition to the classic materials for sliding guides such as steel and bronze, sintered iron has long been regarded as a strong alternative in die making. Thanks to its porosity, it is ideally suited for use as a slide bearing. It also offers high wear resistance and has very good emergency operating features.

07.04.2020 The right material for every requirement in die making

To meet the different requirements for cutting steels used in die making, Meusburger has a large selection of NE blocks for eroding that cover a wide range of materials - including classic steel for through hardening, high-speed steel, powder metallurgical steel and carbide. The blocks for eroding are mainly used for the production of cutting punches and dies and are available from stock in heat-treated and hardened versions. Their thicknesses are perfectly matched to the plates of Meusburger’s standardised die sets.

30.01.2020 Milling cutters especially for hard machining from Meusburger

Meusburger offers the optimal solutions for machining hardened material up to 67 HRC. The hard milling cutters in different variations achieve highest precision and quality. Most milling cutters are used in Meusburger’s own production. This means that the range is perfectly matched to the requirements and materials in mould and die making.

24.09.2019 Meusburger presents their brand new stamping and forming die set at the Blechexpo 2019

16.07.2019 Meusburger presents innovations in the field of workshop equipment

25.06.2019 Standardised stamping and forming die sets for Bihler presses

A brand-new market innovation is now available from Austrian standard parts manufacturer Meusburger and German stamping and forming machine specialist Bihler. In a close cooperation between the two companies, the first standardised stamping and forming die sets were developed with Meusburger standard parts for Bihler NC presses. The new die sets in types ‘tunnel cut’ or ‘spring-loaded guiding plate’ are available for stamping presses with forces up to 400kN and promise to bring enormous savings in time and cost for Meusburger and Bihler customers in future.

21.05.2019 A comparison of different punch attachment options

Meusburger’s comprehensive range of standard parts offers a variety of possibilities for attaching punches - with direct CAD data export and available from stock for fast design and production. Depending on the application and conditions, cutting punches can be mounted or attached differently in the die set. This article takes a closer look at the different types of punch attachments, including the ball-lock system.

23.04.2019 Offset cutting punches at Meusburger

With the offset cutting punches from Meusburger there are many possibilities to configure the contour of cutting punches individually according to your needs. In addition, different materials and head shapes as well as coatings are available. These can be selected quickly and easily using the cutting punches configurator. Thanks to in-house production, Meusburger offers maximum precision and short lead times.

26.02.2019 New embossing elements for die making

05.12.2018 Successful standardisation begins in the design phase

Die Welt wächst zusammen – logistisch und wirtschaftlich. Die Globalisierung erhöht für den Werkzeug- und Formenbau den Wettbewerbsdruck, bietet aber auch die Chance, von Aufträgen in schnell wachsenden Märkten zu profitieren. Gleichzeitig dreht sich die Innovationsspirale immer schneller, was von den Unternehmen Anpassungsfähigkeit und Flexibilität abverlangt. Der hohe Kosten- und Zeitdruck zwingt die Betriebe somit zu einer ständigen Effizienzsteigerung. Ein hoher Grad an Standardisierung über die gesamte Prozesskette bietet hier eine ausgezeichnete Möglichkeit, um Kosten und die Durchlaufzeit von Projekten drastisch zu senken.

15.11.2018 5,000 new plates and bars sizes

09.10.2018 NEW from Meusburger: Blocks for eroding with starting hole

27.09.2018 Proper heat treatment paves the way to success

Not all stress-relieving heat treatment is the same – because only a proper heat treatment process ensures the desired result in the end. That is why Meusburger has been using its own furnaces for almost 30 years. Meusburger stands for top-quality products – only flawless steel from the best-known steelworks can make it through the quality check. Standard parts that are heat-treated for stress relief are right at the beginning of the die and mould making process chain and form the basis of high-quality moulds and dies.

04.09.2018 Meusburger enables universal die set monitoring

The logic distributors by Meusburger in combination with the new limit switches with roller or dome plunger enable universal die set monitoring. The sensors of the limit switches are able to collect signals from different installation positions due to the adjustable roller. The manifold combines several of these signals without voltage drop. Simple and quick installation with maximum flexibility is ensured by the compact design and the many plug-in options.

12.07.2018 E 5636 Strip guiding rail in lengths 60 and 100 mm

21.06.2018 Meusburger presents innovations in the field of workshop equipment

08.05.2018 Innovations for the modular concept

Meusburger presents exclusive and groundbreaking innovations for the modular concept at the Stanztec trade fair. The E 5076 and E 5078 Module guides are now available in configurable lengths. This offers the customer maximum flexibility during the design of die modules. The slide-in aid reduces the processing costs and set-up times to a minimum. With the modular design wizard, the time-consuming and difficult selection of individual plates is a thing of the past.

22.03.2018 New cutting punches and contour bases at Meusburger

13.02.2018 Increased stamping process reliability with precision control devices

06.12.2017 NEW from Meusburger: HFC rough milling cutters

The new high-feed milling cutters WZF 11512 and WZF 11522, or HFC milling cutters for short (HFC stands for High Feed Cutting), are mainly used for roughing. This procedure is particularly economical, as very high cutting speeds and feed rates can be reached. In addition, these milling cutters guarantee higher process reliability through a controlled wear process without cutting edge breakage.

19.09.2017 Meusburger expands its range in the area of gas springs

18.07.2017 Meusburger now offers new guiding elements in the area of die making

20.06.2017 Clamping devices for ergonomic work during polishing

Ergonomics plays a central role in the design of a safe and healthy working environment in many areas. With the new tiltable tables and magnetic clamping balls, which enable ergonomic work during polishing, the standard parts manufacturer expands its workshop equipment range and makes an important contribution for modern workplace design.

23.05.2017 Meusburger expands its range in the area of active parts

The standard parts manufacturer Meusburger now offers three new, innovative components in the area of active parts: a punch suspension piece with radius for fixing and installation of filigree punches, a block-shaped strip lifter with large contact surface and an additional size for the tried and trusted infeed guide for strip widths up to 152 mm.

25.04.2017 New configuration options for Meusburger cutting punches

The standard parts manufacturer Meusburger now offers new configuration options for cutting punches. This includes two different PVD coatings for maximum service life and the configuration of anti-rotation protection for shape punches. The cutting punches can be quickly and easily selected via the new configurator in the Meusburger digital catalogues.

15.03.2017 Achieve maximum precision with the Meusburger guide pillar with centre collar

14.02.2017 Reliable clamping with Meusburger high-pressure clamping equipment

The standard parts manufacturer Meusburger expands its range of workshop equipment especially coordinated to die and mould making with high-quality high-pressure clamping equipment. In addition to the tried and trusted centring vices Meusburger now offers high-pressure vices in three different variations. Due to the integrated power amplifier a clamping force of up to 50 kN is reached. The repeatable accuracy during clamping is 0.01 and enables highest precision in the machining of workpieces.

03.01.2017 NEW from Meusburger - Adjustment unit with even more precise positioning

06.12.2016 NEW at Meusburger – Compact and ready-to-use pilot unit

15.11.2016 NEW from Meusburger – carbide blocks for eroding

25.10.2016 Meusburger launches new consumables for the food processing industry

The standard parts manufacturer Meusburger offers selected consumables with H1-food-safe approval. The high-quality products are therefore especially suitable for the food processing industry. In this sector all substances such as grease, oil, compounds or anticorrosives are subject to high standards so they must be selected with particular care. New in the Meusburger range are for example the VGI 250 S Lubricant and release agent and the VPG 70 FD Food-safe anti-corrosive.

11.10.2016 NEW – Meusburger cutting punches with configurable bases

20.09.2016 New cutting tools at Meusburger: indexable insert tools

30.08.2016 Meusburger offers a comprehensive range of accessories for spring installation

In die making, springs are an essential part to every die set. As a competent partner for die makers Meusburger offers, in addition to springs with round or rectangular cross section and elastomer compression springs in diverse shore hardness, also the most extensive range of accessories for spring installation on the market.

18.08.2016 Safety first! New product group 'Protective equipment' at Meusburger

The theme protective equipment accompanies die and mould makers in their daily working life. To function as a competent full-range supplier, Meusburger expands its range in the area of workshop equipment with the new product group protective equipment. The standard parts manufacturer exclusively relies on the high-quality products from UVEX. The pre-sorted product range enables an easy and time-saving selection of the required protective equipment and as always with Meusburger, is available from stock.

04.08.2016 Meusburger standard components for the modular concept

Meusburger's convenient and cost-effective standard components guarantee an easy installation of die modules. Key advantages when using modules are quick tool changes and therefore reduced downtimes. The Austrian standard parts manufacturer offers users the possibility to use these advantages with its extensive range of products for the modular concept.

15.06.2016 NEW from Meusburger – In-house manufactured cutting punches with round base

The standard parts manufacturer responds to customer requests and now offers a wide range of cutting punches with round bases. These are manufactured in-house within a short time span with the new automated cylindrical grinding machine. Therefore Meusburger can guarantee especially attractive lead times.

31.05.2016 NEW in range from Meusburger – SD- and SZ-Two-pillar die sets

With the new two-pillar die sets, in which the guide pillars are arranged diagonally or centrally, Meusburger enables its customers new and flexible applications. The optimised arrangement of the retainer clip for the pillars and bushes retainer guarantees the SZ Two-pillar die set, central guiding a maximum usable width. The SD Two-pillar die set, diagonal guiding is designed for use in the length and width.

Mould making

14.06.2024 Durable and precise – ejector set guiding from Meusburger

25.04.2024 The multifunctional clamping system for mould making

22.02.2024 Successful work with Meusburger plates

Looking for high-quality plates? As standard parts manufacturer, Meusburger can provide the best possible support in this regard. With over 30 material grades stored on an area of 2.5 football fields and a high-percentage of in-house production, the best quality as well as process reliability and supply security are guaranteed.

12.01.2024 Single nozzle easyFILL EH 4010

29.08.2023 Meusburger presents range at Fakuma

It’s time again – the international trade fair for plastics processing will take place in Friedrichshafen from 17 to 21 October. Meusburger will be attending and showcasing its product range at stands 2313 and 2316 in hall A2. Alongside its range for injection moulders, the wide range of components and the ENGEL injection moulding machine, the spotlight will be on the company’s latest campaign relating to bars.

22.06.2023 Custom-made components

23.05.2023 Optimised set-up time thanks to multi coupler

Often there are long set-up times and unnecessary machine downtimes due to numerous temperature regulation connections. Not only time loss but also quality issues can also result through possible coupling errors. Meusburger offers the perfect solution for optimising set-up times with their system EU and USA multi couplers.

20.04.2023 Meusburger at the Moulding Expo with a new campaign

The Moulding Expo, the most important European event for the mould and die making industry, will take place in Stuttgart from 13 to 16 June 2023. Of course, Meusburger will be there again. In addition to its new products and a comprehensive range for injection moulders, the standard parts manufacturer will be presenting its latest campaign on cavities. Visitors will also be able to find out about standardised and customised solutions for hot runner systems. At the Meusburger stand E41 in hall 1, guests can even watch lunch boxes be produced live on an injection moulding machine from ENGEL.

13.04.2023 Our heart beats for your cavity

At Meusburger you benefit from high-precision components to suit your requirements. As part of the latest campaign from the standard parts manufacturer, find out about the different products available in the range for cavities and why Meusburger can provide you with the best advice. The company has packaged the core message "Our heart beats for your cavity" in two creative videos.

07.03.2023 Higher quality thanks to the cooled compact slide unit

16.02.2023 Easy to design thanks to the Meusburger colour codes

13.01.2023 Precise temperature control with the profiTEMP IM

01.12.2022 The ideal basis for durable injection moulds

11.11.2022 The ideal basis for your injection moulding solution

Whether standard moulds, sliding core moulds, change moulds or micro moulds – Meusburger offers a comprehensive range of products. Customers benefit not only from many years of experience, but also from production from high-grade steel, heat-treated for stress relief, as well as from fast order processing from request to delivery. As usual, all mould bases are available from stock. The standard parts manufacturer’s latest campaign consists of three statements combined with short videos and tells you exactly what makes the mould bases so unique.

04.08.2022 Meusburger presents product range at K 2022

At this year’s K trade fair in Düsseldorf from 19 to 26 October, Meusburger will focus on its standardised mould bases. The standard parts manufacturer will also present its range for injection moulders and both the standardised and the customised solutions for hot runner systems. A special highlight of stand C30 in hall 1 will be the ENGEL injection moulding machine, where visitors can watch a bread box being produced.

28.04.2022 Professional diagnosis with the profiTEMP TM

21.01.2022 Maximum closing force with the powerMOVE

The powerMOVE lever operated lifting plate is an integral part of the hot half in our range of valve gate systems. Matched to the sizes in the plates range, various standardised powerMOVE units are available, which are customised according to the individual requirements. The arrangement of the nozzles can be freely configured.

11.01.2022 Innovations in workshop equipment from Meusburger

22.10.2021 Meusburger highlights at Fakuma

From the 12–16 October Meusburger was represented at Fakuma, the international trade fair for plastics processing in Friedrichshafen, Germany. The range for injection moulders as well as the standard and custom hot runner systems were in the spotlight. The visitors in hall A2 at stand 2313 and 2317 also got the first look at Meusburger’s brand new trade fair stand design. Another particular highlight at the stand was the Engel injection moulding machine, which visitors were able to watch live in action producing bread boxes.

21.09.2021 Low-leakage couplers – for flawless and reliable temperature regulation in cleanrooms

29.06.2021 Optimal gate temperature control made easy

22.04.2021 Reliable and environmentally friendly sealing

30.03.2021 Standardisation in the hot runner sector with the FH mould

In today’s world, standardisation plays a major role for successfully operating a company in most industries. This also applies for the hot runner sector where substantial time and savings potentials are possible through standardisation. The FH hot runner mould from Meusburger is the perfect example. It consists of a complete mould base including a hot runner system.

14.01.2021 Innovative solution for optimal slide retention

Slide retainers are needed to hold slides securely in the end position when the mould is open. With the new E 3050 leaf spring roll stopper, Meusburger has created an exclusive and cost-effective alternative to existing solutions on the market. The compact design enables retaining forces of up to 140 N and is therefore also ideal for holding large slide bodies in their end position. In order to cover a wide range of applications, the leaf spring roll stopper is available in two different variations and three different leaf spring thicknesses.

10.12.2020 The right plate for every project

29.10.2020 New workshop equipment products from Meusburger

In order to meet customers’ needs, the product range at Meusburger is constantly being expanded - like our workshop equipment range in mid-October. New innovations have been added to the product groups surface finishing equipment, assembly equipment and clamping equipment, and there were expansions in the areas of cutting tools and EDM accessories.

16.10.2020 Save time and money with the new clamping configurator

According to a study, a mould making company spends an average of 600 hours per year on machine setup. This time can be significantly reduced by using a zero clamping system. As renowned plate supplier, Meusburger offers an additional service for this. Now customers can order the plates they need to machine with the fitting holes for the clamping bolts of their zero clamping system. This new service will make the value chain for plate machining even more efficient.

22.09.2020 Meusburger provides tried and trusted CAD tool free of charge

Together with their customer Schmidt WFT, Meusburger has developed a CAD tool that is now available to you free of charge. This tried and trusted tool is coordinated with the Siemens NX CAD system and enables designers to carry out a simple and time-saving design process. Configurations of components which are native in the system can be selected and all parameters are automatically adjusted. Installation spaces and the colour table standards developed by Meusburger together with the Association of German Tool and Mould Makers are also integrated in the tool. The parts list is automatically updated when changes are made.

24.07.2020 TT slide unit now available in two new sizes

In addition to the existing sizes with slide surfaces of 12 x 10 mm and 15 x 12 mm, the tried and trusted E 3310 TT slide unit from Meusburger has been expanded with two new sizes with slide surfaces of 8 x 6 mm and 18 x 14 mm. The ready-to-use slide unit reduces overall costs during design and mould manufacturing. In addition, daily work is facilitated through the compatibility of the components and the direct download of CAD data including installation spaces. Small slide units are in particular demand for complex moulds.

25.06.2020 Build-in cylinder with flange – new diameter available from stock

Meusburger offers the compact build-in cylinder with flange ideal for the smallest installation spaces. Thanks to uncomplicated incorporation and the supplied screws, it can be installed in no time at all. In addition, the two-step installation hole protects the sealing during installation. New in range is the build-in cylinder with flange with a piston diameter of 20 mm.

15.05.2020 Cavity pressure sensors: single wire vs. coaxial

The cavity pressure is an important parameter in process monitoring during plastic injection moulding. Pressure sensors are therefore indispensable for comprehensive mould monitoring. The use of high-quality piezoelectric sensors leads to optimal process quality and increases part quality sustainably. Two different technologies are available on the market for charge transfer: single wire and coaxial cables. We will show you the essential differences and characteristics of these two variants.

30.04.2020 Meusburger premium power clamps for injection moulding

17.04.2020 Material grade 1.2738 TSHH now available from stock

Reducing processing time and optimising costs is especially important for injection moulds with moderate shot weights. In addition, flawless surface quality is often required for injection moulded parts. 1.2738 TSHH steel has long been established on the market for this purpose. This steel is especially useful in the automotive industry, but also for consumer goods. Meusburger now offers cavity plates and standard plates in the material grade 1.2738 TSHH available from stock.

10.04.2020 Position sensing for high process reliability

Position sensing plays an important role in a reliable injection moulding process. Whether for monitoring the end positions of a slide, ejector set or hydraulic cylinder – mechanical and inductive sensors have become essential in modern mould and die making. Here is an overview of the most common variations for position control of components in the mould.

06.02.2020 Top reliability when operating 3-plate moulds

Latch locks are used to control moulds with 2 split lines, often referred to as 3-plate moulds. With the new E 1817 latch lock, Meusburger has created an exclusive and cost-effective alternative to existing products on the market, such as round or flat latch locks. Thanks to its simple mechanical functional principle, the new latch lock offers maximum reliability in the control of 3-plate moulds. In addition, it features a compact design as well as low machining effort prior to its installation.

30.01.2020 Milling cutters especially for hard machining from Meusburger

Meusburger offers the optimal solutions for machining hardened material up to 67 HRC. The hard milling cutters in different variations achieve highest precision and quality. Most milling cutters are used in Meusburger’s own production. This means that the range is perfectly matched to the requirements and materials in mould and die making.

29.10.2019 Market innovations presented by Meusburger at the K trade fair

At this year’s K trade fair in Düsseldorf, the Meusburger stand featured the new configurator for hot runner moulds. The new cavity pressure sensors and many other Meusburger products were also presented to visitors, alongside the unmissable hot runner and control systems, WBI Knowledge Management and ERP software.

20.08.2019 Meusburger at the K 2019 with market innovations

At this year’s K trade fair in Düsseldorf (16 to 23 October), the Meusburger stand (hall 1, stand C30) will feature the new and one-of-a-kind configurator for hot runner moulds. In addition, the new cavity pressure sensors and many other Meusburger products will be presented. Of course the divisions of hot runner and control systems, Knowledge Management, and ERP will also be presented.

13.08.2019 A new generation of ejectors for inclined ejection units

For easier demoulding of internal undercuts in plastic parts, ejectors for inclined ejection units can often be used instead of slide units. With the new E 3270 Inclined ejection unit, Meusburger offers a cost-effective and ready-to-use alternative to the existing ejectors for inclined ejection units on the market. The part geometry is created with a block for eroding which allows for maximum design flexibility. The DLC coating of the ejector rod ensures minimal wear, best sliding properties and ultimately a long service life.

16.07.2019 Meusburger presents innovations in the field of workshop equipment

18.06.2019 Cavity pressure measurement for increased process efficiency in injection moulding

According to the motto ‘everything from one source’, in addition to standard parts for temperature and end position control, Meusburger now also offers sensors for cavity pressure measurement. With the matching connecting cable, these are compatible with all systems for analysis currently available on the market. The range includes two types each for direct and indirect measurement as well as suitable mounting accessories and connection cables - as usual available from stock with simple CAD data download from the Meusburger web shop.

02.04.2019 A hot runner mould in just five minutes: with Meusburger, you can!

With the brand new Meusburger configurator for hot runner moulds a complete mould base including hot runner manifold can be customised with just a few clicks. The configurator offers highest flexibility, immediate creation of the 3D data and immediate price display. This world first on the market is the result of the very good cooperation between Meusburger and PSG.

16.03.2019 Compact design with the Meusburger locking cylinder

22.01.2019 Exclusively at Meusburger: DLC coated flat guiding stock

18.12.2018 Tried and trusted components now available in stainless steel

Stainless steel components are mainly used in processing corrosive plastics or in clean room technology (e.g. medical or food processing applications). Meusburger has expanded its product range especially in the temperature regulation components, ejectors, and demoulding product groups with numerous new stainless steel components.

15.11.2018 5,000 new plates and bars sizes

09.10.2018 NEW from Meusburger: Blocks for eroding with starting hole

27.09.2018 Proper heat treatment paves the way to success

Not all stress-relieving heat treatment is the same – because only a proper heat treatment process ensures the desired result in the end. That is why Meusburger has been using its own furnaces for almost 30 years. Meusburger stands for top-quality products – only flawless steel from the best-known steelworks can make it through the quality check. Standard parts that are heat-treated for stress relief are right at the beginning of the die and mould making process chain and form the basis of high-quality moulds and dies.

13.09.2018 Leakage problems at high temperatures?

Increasing with high temperatures, leakage problems can occur at various points. Sooner or later, the typical brass plugs can lead to leaks – this results in machine downtimes and increased maintenance intervals. It is often assumed that the problem is the sealant used, but this is usually not the reason: Due to different coefficients of expansion of brass plugs and steel plates, setting occurs during heating and cooling of the mould which consequently leads to leakage.

04.09.2018 Meusburger enables universal die set monitoring

The logic distributors by Meusburger in combination with the new limit switches with roller or dome plunger enable universal die set monitoring. The sensors of the limit switches are able to collect signals from different installation positions due to the adjustable roller. The manifold combines several of these signals without voltage drop. Simple and quick installation with maximum flexibility is ensured by the compact design and the many plug-in options.

24.07.2018 Meusburger presents the smallest ready-to-use slide unit on the market

The new member of the Meusburger family of compact slide units is the E 3310 TT-Slide unit, which features a compact design. The ready-to-use slide unit reduces overall costs during design and tool manufacturing. In addition, daily work is facilitated through the compatibility of the components and the direct download of CAD data including installation spaces. Small slide units are in particular demand for complex moulds.

10.07.2018 Stamps with latching function for even higher process reliability

Marking stamps are used for clear marking of injection-moulded parts. To prevent unintended movement of the arrow insert, Meusburger now offers stamps with a latching function. These ensure even higher process reliability during the injection moulding process, and prevent parts being marked incorrectly.

21.06.2018 Meusburger presents innovations in the field of workshop equipment

05.06.2018 A must-have in modern die and mould making: DLC coated components

24.04.2018 NEW from Meusburger: E 7048 Build-in cylinder with flange

Ideal for the smallest installation spaces, Meusburger now exclusively offers the compact build-in cylinder with flange. Thanks to an uncomplicated incorporation and the supplied screws, it can be installed in no time at all. In addition, the two-step installation hole protects the sealing during installation.