Contacto

Estaremos encantados de atenderle de lunes a viernes desde las 8:00 hasta las 17:00. Haga clic en este enlace para buscar el interlocutor que le corresponde por zona.

Sede de Wolfurt

+43 5574 6706-0

Carrito de la compra {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Artículo Cambiar carrito

Observaciones

| Imagen | Artículo | Unidades | Precio por unidad | Precio total | Precio total con descuento | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

clientes

- Fabricación de moldes

- Matricería

- Fabricación de herramentales

- Diseñadores

- Fabricantes de moldes de inyección

-

Productos

- Productos nuevos

- Portamoldes

-

Portatroqueles

- Portatroqueles estándar SV

- Portamatrices de precisión SP

- Portatroqueles SH de dos columnas, guiado trasero

- Portatroqueles SD de dos columnas, guiado diagonal

- Portatroqueles SZ de dos columnas, guiado central

- Plates for SM-modular concept

- PORTAMATRICES DE TROQUELADO Y DOBLADO

- Sistema de amarre H 3000

- Placas P

- Barras N

- Placas y barras

- Componentes E

- Sistemas de cámara caliente

- Regulación de cámaras calientes

- Suministros para talleres

- La empresa

- Trabaje con nosotros

- Servicio

Hot half and customised complete systems

Customised complete systems

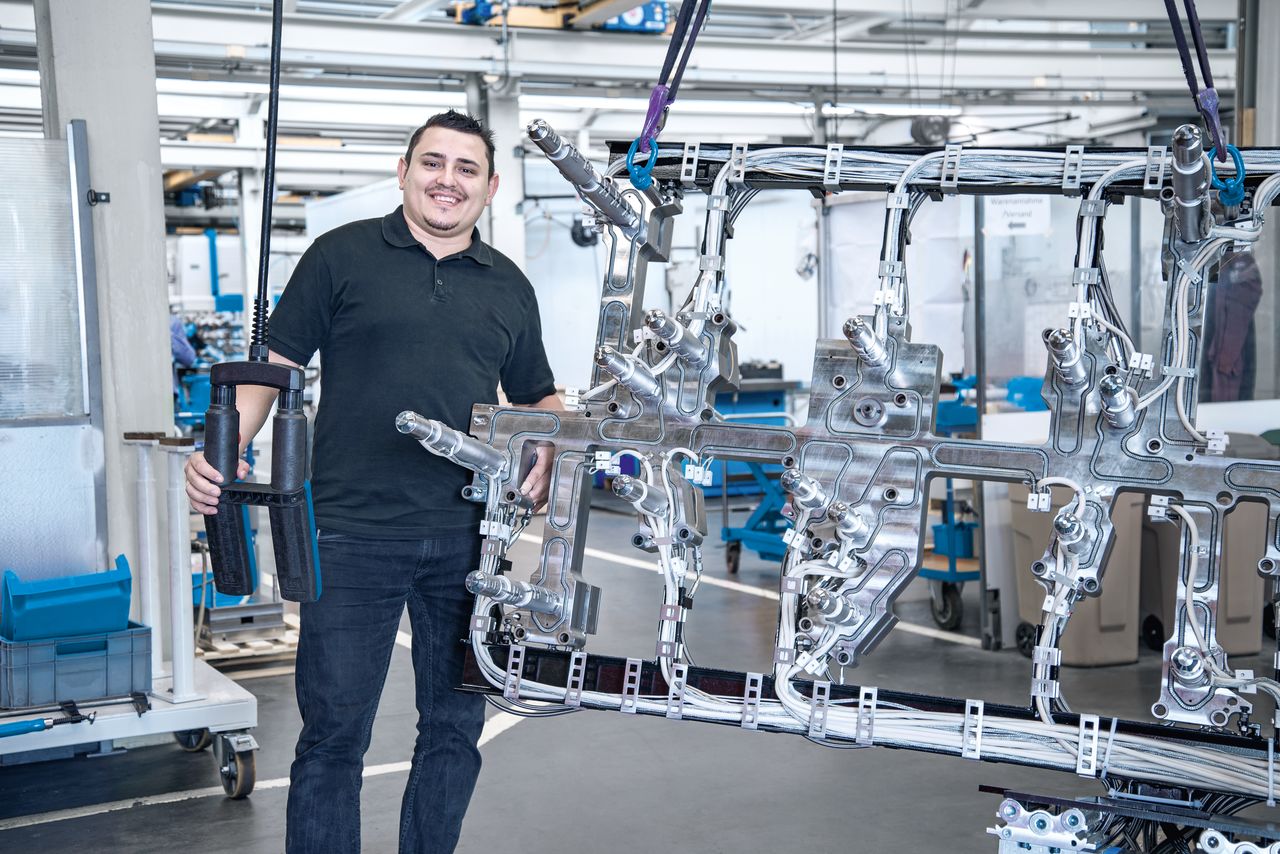

Our systems are as individual as your applications. Based on standardised hot runner components, we complete our systems in such a way that they are customised to your needs and requirements and guarantee an optimal production process according to injection moulding peripherals. For Meusburger, the focus is the best possible handling of the systems during service and installation and, of course, optimum quality for your injection moulded part.

Ready to install and connect hot runner systems

The hot runner system with smartFILL screw-in type hot runner nozzles is delivered completely assembled and the function of the system has already been tested. The hot runner manifold just has to be inserted into the fixed half of the mould and screwed to the cavity plate. There is no need to adjust the height of the clamp plate because the hot runner nozzle and manifold are screwed together, thus ensuring that the hot runner system is sealed.

Hot half

Just the cavity plate with the cavities is missing on the fixed half of the mould. Meusburger supplies the customised hot half, either with open nozzles or as a valve gate system. You also have the choice of using the ‘slide seal’ or ‘shot’ nozzle variant. For valve gate applications, you can choose between pin actuation individually per nozzle or pin actuation via lifting plate. Of course, the electrical connections and the media connections are selected, placed and connected exactly according to customer requirements.

The hot half offers the highest level of comfort both in the project planning for the mould maker and in the production for the injection moulder.

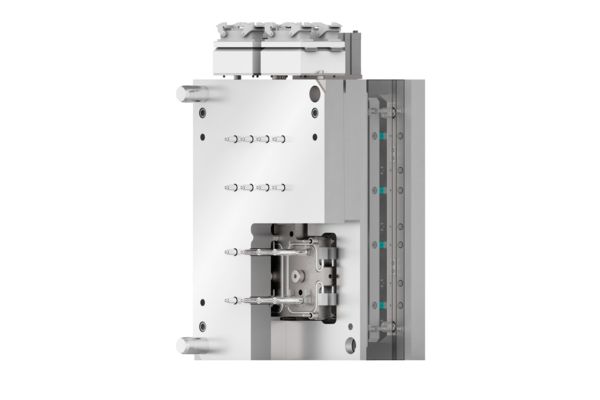

powerMOVE

The powerMOVE lever operated lifting plate is part of the hot half in our range of valve gate systems. Matched to the sizes of our plates, various standardised powerMOVE units are available, which are customised according to the individual requirements of your application. You can define the position of the nozzles yourself. With the powerMOVE you get a cleanroom compatible and self-lubricating pin actuation system. The lever mechanism ensures ideal force and speed for the opening and closing of the pins during the injection moulding process. With no additional control system necessary, consistent high quality of injection moulded parts is ensured.

La empresa

Meusburger México S. de R.L. de C.V.

Acceso IV #31-K Zona Industrial Benito Juárez CP 76120

Querétaro, Querétaro

+52 442 2450280

sales@meusburger.mx

Quick Links

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]