Securing competitive advantages in the long term

Globalisation increases the competitive pressure on die and mould makers, but also offers the chance to profit from orders in fast-growing markets. At the same time the innovation wheel is turning ever faster, which requires adaptability and flexibility from companies. The high cost and time pressure forces companies to constantly improve their efficiency.

Through a systematic and consistent standardisation of products and processes, major savings in time and cost can be made, thus creating the decisive basis for the long-term success of a company. When considering the entire life cycle of a product, the ability to influence cost is highest during the design stage.

Smooth interchangeability

In series production, non-productive times and waiting times caused by broken dies are reduced by using standardised parts as these guarantee smooth interchangeability and can be quickly replaced.

Reduced deformation through stress-relieving heat treatment

To achieve the best quality, we rely not only on the precise in-house production of our plates, but also on our own furnaces with a total capacity of 240 tonnes. The low-deformation material itself has a big influence on the manufacturing and maintenance costs of the die: thanks to the high-grade steel, which is heat-treated for stress relief, and to the exact form and position tolerances, subsequent costs can be reduced.

Top precision

In summary, one can say that die makers can benefit in many ways from the consistent use of Meusburger standard parts because high-precision end products ultimately depend on high-precision die sets. The modular system allows an almost unlimited number of possible combinations while maintaining the highest and most consistent precision. Moreover, the Meusburger standard hole pattern with anti-rotation protection enables highly accurate positioning of the guide holes and correct assembly of the upper and lower part. The alignment edge allows for a quick alignment of the plate on the machine. The ventilation groove ensures the controlled escape of air when sliding guides are used.

Available from stock

Tried and trusted standard die sets with or without pre-drilled holes, precision die sets for increased accuracy requirements and two-pillar die sets with two linear guiding units arranged at the back, diagonally, or centrally, depending on the type. Our standard components for die making are directly available from stock in the shortest time possible.

Discover our range

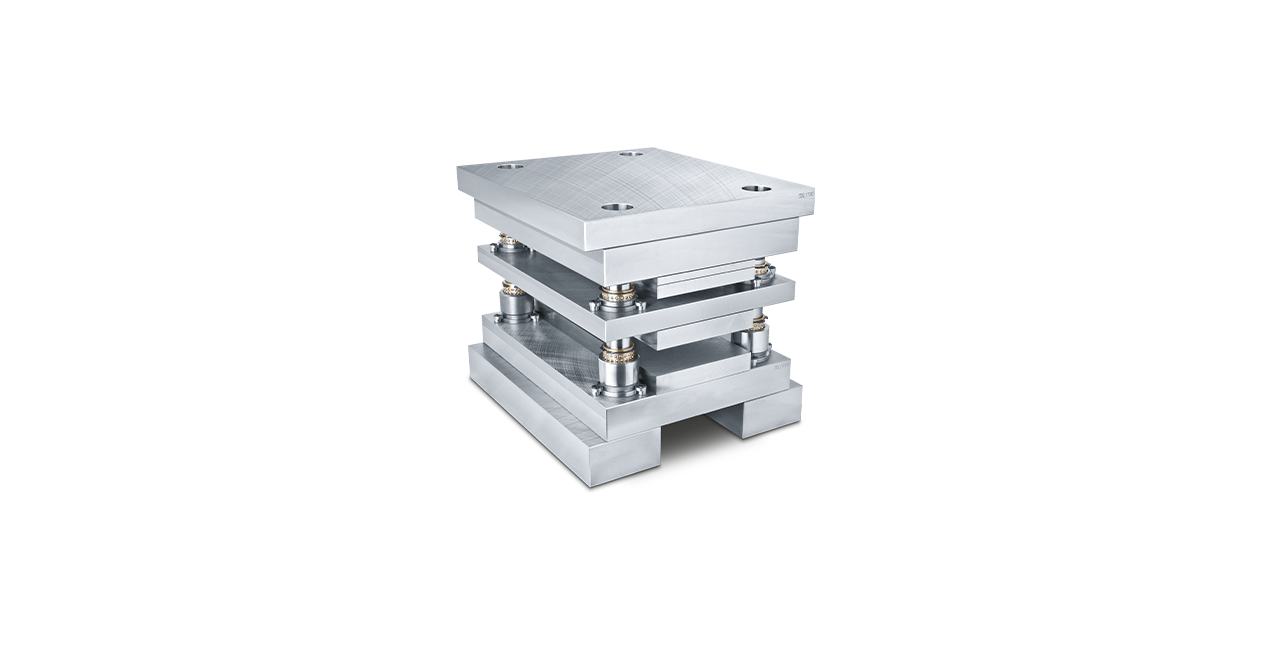

SV – Standard die set

Our tried and trusted standard die set is available in sizes ranging from 156 x 156 to 696 x 1396 mm. The guide pillar can be fitted to the head plate or the base plate, depending on the application.

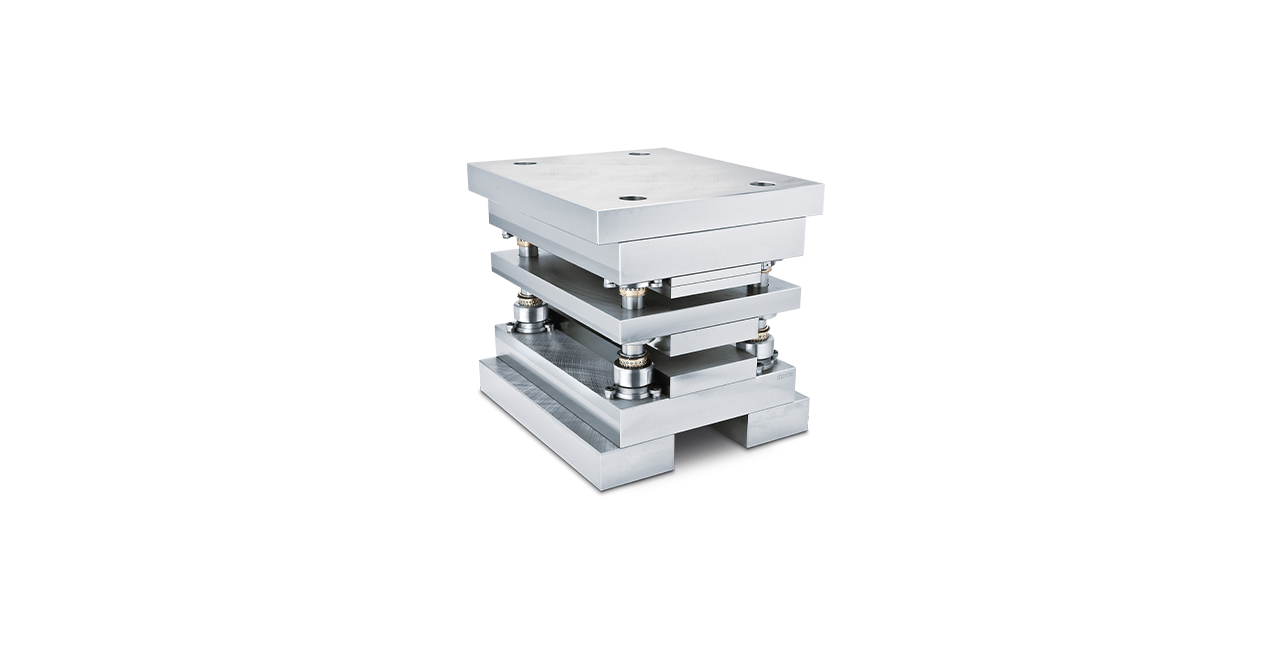

SP – Precision die set

In our precision die set, the guide pillar is fitted to the backing plate, which ensures optimum transfer of the guide system’s shear forces. It is available in sizes 196 x 196 to 496 x 696 mm.

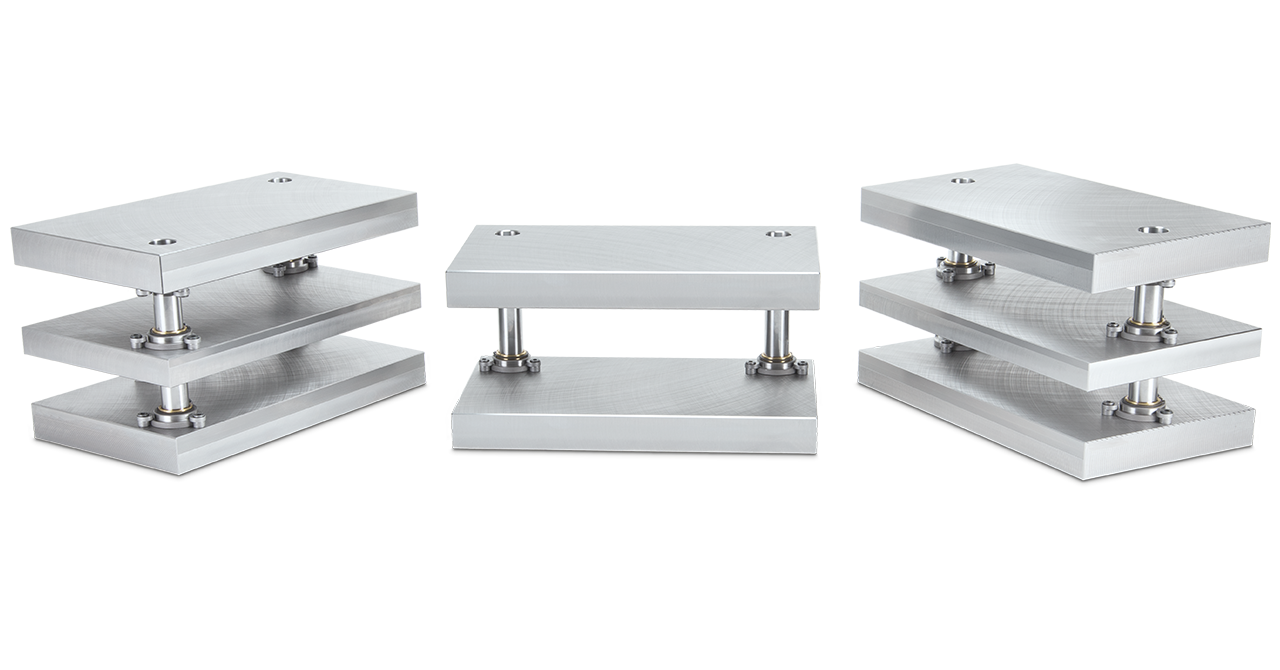

SH, SD, SZ – Two-pillar die sets

Flexible application options of the die sets through different arrangement of the guide pillars. Two-pillar die sets with diagonal or central guiding selectable with and without backing plate.

Two-pillar die sets, back guiding Two-pillar die sets, diagonal guiding Two-pillar die sets, central guiding

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]