Contact

We are gladly available for you from Monday to Friday from 8:00 to 17:00. Use this link to find the contact persons for your region.

Headquarters Wolfurt

+43 5574 6706-0

Shopping cart {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Items Change shopping cart

Remark

| Picture | Items | Pcs | Single price | Total price | Total price incl. discount | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Customers

- Mould making

- Die making

- Jigs and fixtures

- Area for designers

- Injection moulders

- Products

- Company

- Job opportunities

- Service

We are constantly on the move.

News

Here you can find news about our company as well as current product highlights.

Published on: 08.08.2024

10 years of Meusburger India

Since 2014 Meusburger has been present with a subsidiary company in India. Thus, we have been able to support our customers directly and locally for a decade now.

Published on: 21.03.2024

Our opening hours over Easter

Easter is just around the corner and in Austria the children are excited about searching for colourful Easter eggs hidden inside and outside. As not only the traditions but also the public holidays can be different depending on the country and region, we would like to keep you informed of our opening days over this period.

Published on: 22.02.2024

Family business with experts in every area

We celebrate 60 years of Meusburger. Thanks to the substantial growth of our company over the last few decades, we quickly realised that each person has valuable special skills and talents.

Published on: 20.02.2024

Results of the market barometer survey in mould and die making

Together with the WBA Tooling Academy, we have developed and conducted a survey. The goal was to create an international market barometer of current trends, developments and challenges in our industry. The survey results are now available.

Published on: 09.01.2024

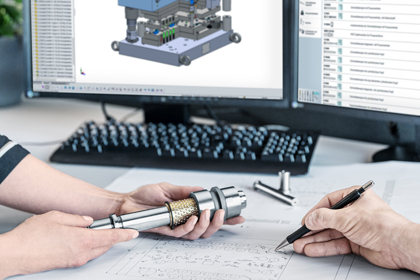

NX tool

In cooperation with our customer Schmidt WFT, we have developed a CAD tool,

which is now available to you free of charge.

Published on: 05.12.2023

Christmas and New Year’s opening times

The holidays are about to begin. This means that our employees will also be spending time with their loved ones. To stay informed on when we are open in December and over the New Year, you can find our opening hours here.

Published on: 02/10/2023

Welcome to the next level

After an intensive preparation period, the time has finally come – the new Meusburger portal is up and running in parallel with the previous version. With it, you get an insight into the next level of the Meusburger online world. The portal is easy to use for any target group with just a few clicks and will guide you to your goal as quickly and intuitively as possible.

Published on: 18.07.2023

For more control and efficiency

True to our motto ‘everything from one source’, we not only have standard parts for temperature and end position control, but also offer sensors for cavity pressure measurement in our range. Stay in control and improve your part quality.

Published on: 30.05.2023

Precise cutting in one work step

The innovative GMT 6000 Cutting and grinding machine enables efficient finishing of ejector pins, cutting punches, and many other parts. In just one work step the workpiece is shortened with allowance and ground precisely to the desired length. The stable design of the machine guarantees exact length and angle tolerance with just one setting, with repeatable accuracy and consistent quality.

Published on: 14.03.2023

Search, find, win

Tell us how many components you spot in the picture, and with a bit of luck you could win snacks for your entire team.

Published on: 18.11.2022

Increase capacity in your incoming goods area

Don’t waste time and effort sorting the individual items from your order into the correct project, drawing or parts list and get an extended product label instead that lists all the items relevant to you.

Published on: 17.10.2022

Our specifications document template for die making

To make sure you don't forget anything when creating your company specifications document, download our template today and see for yourself.

Published on: 04.08.2022

Our solution support guide for injection moulders

Do you need a practical reference guide to optimally identify and fix defects in your moulded part? Our cooperation with the SKZ Plastic Centre in Würzburg makes it possible!

Published on: 10.07.2022

No more time-consuming imports of part lists

Saving the parts list as a table, sending it via email, and then copying it - that can take a lot of time. This is why we have now enhanced our digital catalogues so that you can import your parts lists in just a few clicks, or even send them directly to your colleagues. Learn more about the new features.

Published on: 04.11.2021

Meusburger India has moved

Our subsidiary company in India moved into a new building at the beginning of October. This gives us the opportunity to further strengthen our presence and expand our services in India.

Published on: 05.10.2021

Our plates lead to your success

We are the leading leading manufacturer of plates for mould and die makers and that’s not by chance! All our plates are made in Austria and our extensive stock guarantees supply security even in challenging times.

Published on: 14.09.2021

Available faster globally

Fast delivery in case of emergencies – one of the many advantages that make us your ideal partner. So far this has mainly applied to Europe and China. But now, we have good news for our business partners with headquarters or branches in Mexico and India: warehouses in their own country.

Published on: 17.08.2021

Free webinars at Meusburger

From September to the end of 2021, we will offer a variety of free webinars. Find out what topics we will be covering in the coming weeks in this post.

Published on: 13.04.2021

10 + 1 years of Meusburger China

Meusburger China was founded in 2010 with two employees.10 + 1 years later, the company's primary goal is optimisation. But what's the deal with the 10 + 1 year?

Published on: February 09, 2021

Colour code standards

We have succeeded in creating standardised colour codes for 3D CAD design in mould and die making in cooperation with the Association of German Tool and Mould Makers.

Published on: 04.02.2021

10 years of standardisation in die making

We have been developing innovative solutions for die making for over 10 years. But how did we get involved in this area? Let’s take a look into the past.

Published on: 02.02.2021

Everything you need to know about gas springs – Part 4

In the fourth part of our series ‘Everything you need to know about gas springs’ we have summarised all information about installation and maintenance of gas springs for you. You will also find valuable tips on correct storage.

Published on: 12.01.2021

Everything you need to know about gas springs – Part 3

In the third part of our series ‘Everything you need to know about gas springs’ we focus on the gas springs wizard. Thanks to our wizard you can quickly and easily find the right gas spring for your project.

Published on: 08.12.2020

Everything you need to know about gas springs: part 2

In the second part of our series ‘Everything you need to know about gas springs’ you will learn all about the different types. These differ in their construction and, as a result, also in their size and initial force. In addition, the safety features of the gas springs are designed differently depending on the type.

Published on: 03.12.2020

Innovations for the modular concept

The existing range of two-pillar die sets has been expanded by eight new sizes from 396 796 to 496 996 mm, which are especially suitable for the modular concept.

Published on: 17.11.2020

Everything you need to know about gas springs: part 1

In the first part of our series ‘Everything you need to know about gas springs’, we provide general information, such as which one is suitable for which application or a comparison with conventional system compression springs.

Published on: 12.10.2020

Configurator update

With our mould making update, we also added innovations for the configurator of FH hot runner moulds. We considerably expanded our range of nozzles as well as the selection of plastic materials.

Published on: 08.09.2020

Creating a habitat for bees

The bee is one of the most important organisms in our ecosystem. Its extinction would have tremendous consequences for the Earth. We as a community can come together to prevent this from happening and we have already taken steps towards this cause.

Published on: 11.08.2020

O-ring seals – in perfect shape, part 3

In addition to the correct selection of O-ring seals, the correct introduction of the O-ring groove is essential for the optimum sealing result. In the third part of our series ‘O-ring seals – in perfect shape’ we show you how you can save time during production with our countersink for O-ring seals, and increase the quality of the O-ring groove at the same time.

Published on: 21.07.2020

O-ring seals - in perfect shape, part 2

In the second part of our series ‘O-ring seals – in perfect shape’ we show you what to consider when planning and designing the O-ring seal groove.

Published on: 21.07.2020

Meusburger expands its range of standard elements

In the area of clamping elements, in addition to the standard horizontal toggle clamps, the range is supplemented with a reinforced version. The HWS 201 clamping elements have a more robust design and components can be clamped with higher retaining forces. This makes them particularly suitable for fast clamping in series production.

Published on: 30.06.2020

O-ring seals - in perfect shape, part 1

In this first part, we explain the different sealing types, installation options and materials of O-rings especially for mould making.

Published on: 04.06.2020

Material grade 1.2738 TSHH now available from stock

Reducing processing time and optimising costs is especially important for injection moulds with moderate shot weights. In addition, flawless surface quality is often required for injection moulded parts. 1.2738 TSHH steel has long been established on the market for this purpose. This steel is especially useful in the automotive industry, but also for consumer goods.

Published on: 30.04.2020

Expansion of plate thicknesses

In the recent product update, we were able to expand our range of plates and bars to more than 1,300 dimensions. In addition to numerous expansions, over 300 thicknesses were introduced for the first time for the material grades 1.1730, 1.2085 and 1.2312.

Published on: 26.03.2020

Fully stocked warehouse thanks to in-house production

Especially now, it is particularly important to have a reliable partner at your side that you can count on. A full raw material warehouse, the largest central standard parts warehouse and also a high degree of in-house production ensures that we can continue to supply you with all the products you need.

Published on: 06.02.2020

Always up to date with CADClick

CADClick is available in the Meusburger shops, both online and offline, as a strong, consistent, and always innovative CAD connection.

Published on: 14.01.2020

New features in the Meusburger shops

In addition to a completely new look for the shop start pages for mould making, die making and machine and jig construction, the update at the turn of the year also brought technical innovations. In particular, new functions have been added to the wizard for stamping and forming die sets and the configurator for hot runner moulds. See the changes for yourself!

Published on: 14.01.2020

2019 year in review

The last year had so much to offer: interesting product innovations, exciting events, big changes in the company and many great times with our customers. Thank you!

Published on: 20.12.2019

Meusburger joins forces in 2020

Our goal is to support you in your daily work to guarantee you efficient mould making. Since the takeover of PSG in 2016, we have been working very closely with the hot runner and control systems specialist. To offer you further advantages, we will fully integrate PSG in our company during 2020. This way we can combine and develop our extensive know-how even better for you under one brand: the Meusburger corporate brand.

Published on: 12.12.2019

Our versatile systems for demoulding

Our extensive range of demoulding products includes many tried and trusted items such as two-stage ejectors, components for controlling 3-plate moulds, and different demoulding aids.

Company

Meusburger India Pvt Ltd

#20 A/2, Block B, 1st Cross KIADB Road, Peenya 1st Stage

Bangalore – 560058

+91 80 283655-30

sales@meusburger.in

Quick Links

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]