Contact

Nous sommes volontiers personnellement à votre disposition du lundi au vendredi de 8:00 à 17:00 heures. Veuillez cliquer sur le lien suivant afin de trouver les interlocuteurs pour votre région.

Siège de Wolfurt

+43 5574 6706-0

Panier {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Articles Changer le panier

Remarque

| Image | Articles | Pces. | Prix à l’unité | Total | Total remise incluse | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Clients

- Construction de moules

- Construction d’outils de découpe

- Construction de machines et gabarits

- Concepteurs

- Moulistes injecteurs

- Produits

- Entreprise

- Carrieres

- Service

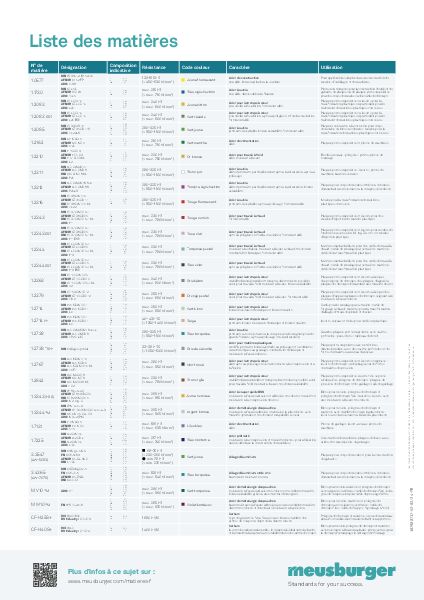

Notre gamme sélectionnée permet d’avoir la matière adéquate pour quasiment toute application.

1.2343 / 1.2343 ESU Hot-work steel

Designation

| DIN: | X 37 CrMoV 5-1 |

| AFNOR: | Z 38 CDV 5 |

| UNI: | X 37 CrMoV 5-1 KU |

| AISI: | H11 / H11 ESR |

Indicatory analysis:

| C | 0.38 |

| Si | 1.00 |

| Mn | 0.40 |

| Cr | 5.30 |

| Mo | 1.20 |

| V | 0.40 |

Strength:

max. 230 HB

(≈ max. 780 N/mm²)

Thermal conductivity at 200 °C:

27 W/m K

Character:

high-alloy hot-work steel with high toughness and heat resistance, hot cracks resistance and good thermal conductivity; for very high requirements available in grade *ESR (Electro-Slag Remelted)

Application:

moulding plates and inserts for plastic injection mould tools; *ESR for applications for die casting (Al, Mg, Zn)

Treatment by

highly suitable:

Polishing

very easily feasible (graining):

Etching

EDM:

in the hardened and tempered condition, treat again for stress relief about 20 °C below the last tempering temperature

Nitriding:

increases the wear resistance and prevents the bonding of casting material

Hard chroming:

in special cases

Heat treatment:

Annealing:

750 to 800 °C, about 4 to 5 hours slow controlled cooling of 10 to 20 °C per hour to about 600 °C; further cooling in air, max. 205 HB

Hardening:

1000 to 1040 °C

15 to 30 minutes keeping curing temperature

quenching in water/oil/air

obtainable hardness: 50−56 HRC

Nitriding:

Before nitriding stress-relief annealing is recommended at 550 °C. (Meusburger standard)

A treatment at 525 °C in ammonia gas results in a surface hardness of approx. 55 HRC

Tempering:

slow heating to tempering temperature immediately after hardening; minimum time in furnace: 1 hour per 20 mm part thickness; repeated tempering is recommended

Tempering chart:

High temperature strength chart:

TechnicalTip:

- susceptible to corrosion; during maching, continuous corrosion protection has to be ensured (especially during wire EDM)

- 1.2343 ESR is highly suitable for mirror polishing

Vers l’aperçu de la construction de moules Vers l’aperçu de la construction d'outils de découpe

1.2343 Available in the web shop as:

1.2343 ESR Available in the web shop as:

Data sheet 1.2343 (ESR)

Entreprise

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

P-Standard plates

P-Standard plates

Standard bars

Standard bars NR-Round bars

NR-Round bars NE-Blocks for eroding

NE-Blocks for eroding

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]