Contact

We are gladly available for you from Monday to Friday from 8:00 to 17:00. Use this link to find the contact persons for your region.

Headquarters Wolfurt

+43 5574 6706-0

Shopping cart {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Items Change shopping cart

Remark

| Picture | Items | Pcs | Single price | Total price | Total price incl. discount | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Customers

- Mould making

- Die making

- Jigs and fixtures

- Area for designers

- Injection moulders

- Products

- Company

- Job opportunities

- Service

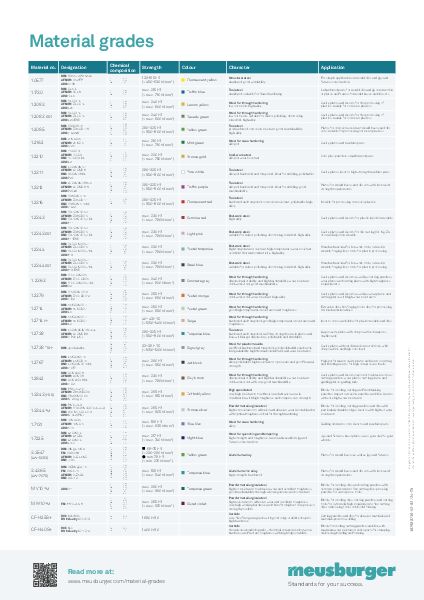

In our selected range you can find the right material for virtually any application.

3.3547 Aluminium alloy

Designation

| DIN: | AlMg4,5Mn / EN AW - 5083 |

| AFNOR: | A - G4,5MC |

| UNI: | 7790 |

| AISI: | - |

Chemical composition:

| Si | 0.40 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.40-1.00 |

| Mg | 4.00-4.90 |

| Cr | 0.05-0.25 |

| Zn | 0.25 |

| Ti | 0.15 |

Strength:

■ 68 - 75 HB

(≈ 230- 260 N/mm²)

● min. 78 HB

(≈ min. 270 N/mm²)

Thermal conductivity at 100 °C:

110-140 W/m K

Character:

not hardenable, homogenised, annealed aluminium alloy with particularly good machining and welding properties; excellent dimensional stability; ideally suited for anodising, hard chromium plating and chemical nickel plating; very high resistance to corrosion

Density: 2.66 kg/dm3

Coefficient of thermal expansion: 24.2 10-6 m/mK

Max. temperature permanent/short term: 90/110 °C

Application:

plates for mould tools, rotary tables, machined components for machine

and jig construction, moulds for prototypes and foamed parts

Treatment by

possible

Polishing, EDM, etching

Ideally suited:

Machining, welding

Heat treatment:

Note: Subsequent heat treatment may lead to

a deterioration of the mechanical properties.

Available in the web shop as:

Datasheet 3.3547

Company

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

Quick Links

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Standard bars

Standard bars NR-Round bars

NR-Round bars

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]