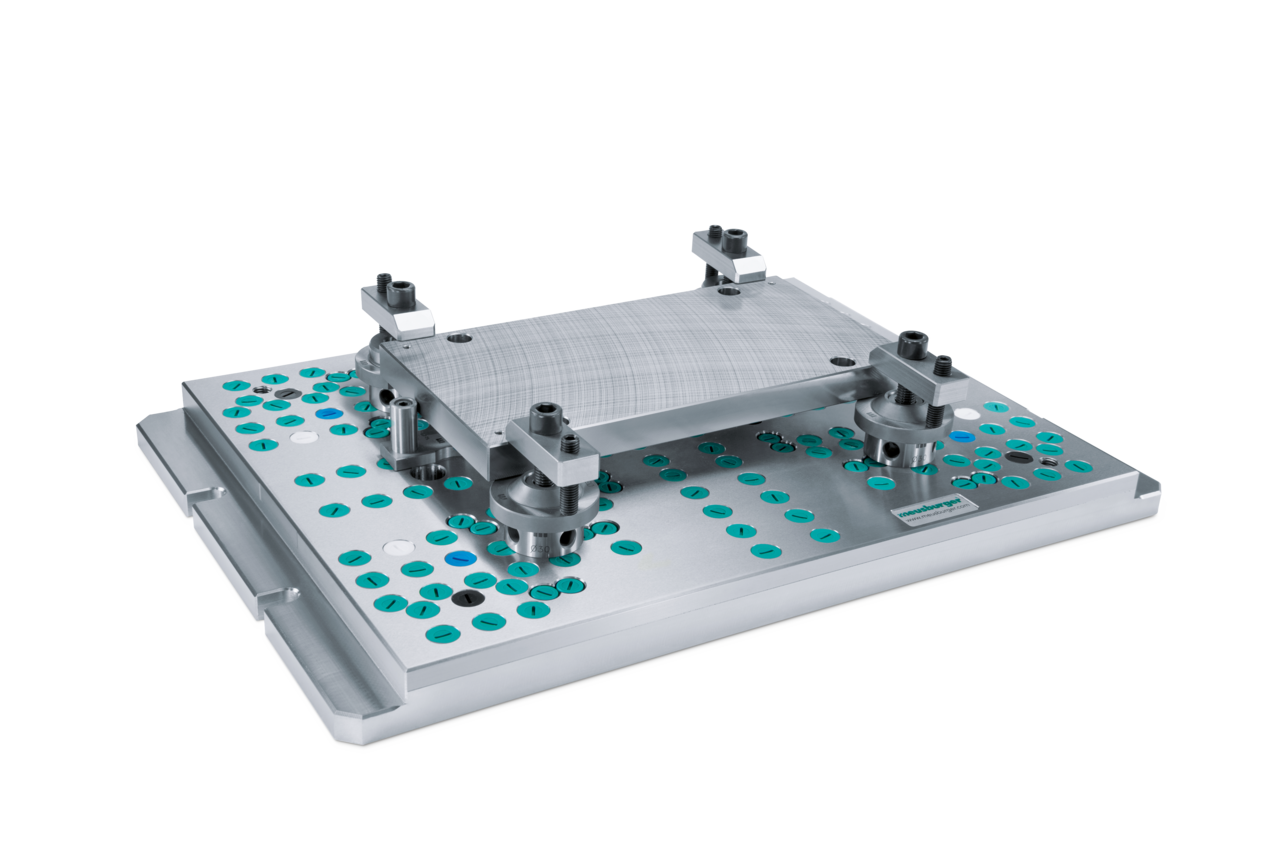

The H 1000 clamping system is an innovative in-house development by Meusburger.

With the H 1000 you will not only work quickly and efficiently but also with absolute precision and repeatability. The standard parts are aligned and clamped where it matters for the mould function, i.e. in the guide holes.

You too can profit from the many benefits of the H 1000.

- Improve the quality of your moulds by precise clamping in the µ-range with repeatable accuracy

- Reduce your processing time by substantially reducing fitting time

- Simplify programming by clamping without obstructive contours

- Minimise the risk of collision by using expansion rings for clamping

- Use pallets for various special clamping tasks

Clamping of inserts

The tried and trusted H 1000 clamping system also allows clamping of NF inserts.

Any number of clamping supports with centring can be fixed into the fitting holes of the H 1000 base plate. In the insert, the clamping spigots are introduced into provided fitting diameters with a thread. Clamping spigots with an undersized fitting diameter are available for machining before hardening. Now the insert is simply placed onto the clamping support and tightened with locking sleeves. Five sides of the part remain free from interfering contours. The distance from the base plate can be increased in 40 mm steps in combination with

H 1030 centring support extensions. As the clamping supports clamp centrally, repeatability in the µ range is guaranteed.

- All existing coordinates of the H 1000 can be used for flexible clamping support configuration.

- Ideal for 5-side machining in combination with the H 1030 centring support extensions.

- Repeatability in the µ range with zero point centring

- Non-tilting or twisting positioning and removal of the parts

- The clamping supports can withstand the maximum feed during cutting

Technical tip - Clamping of NF inserts

H 20100 Clamping plate with 20 mm grid

- Flexible clamping of workpieces through 20 mm hole grid

- You can save time during set-up on the machine due to high-precision alignment edges

- Easy installation of the clamping plate, with repeatable accuracy - also on the existing H 1000 Clamping system

H 1000 Wizard

With our H 1000 Wizard you can quickly and easily configure your personal H 1000 Clamping system.

You can first select the desired plate size and then easily assemble the clamping options for cavity plates and ejector plates required for your diameters. The fully automatic calculation of required clamping elements ensures that our clamping system is supplied completely.

Optionally, additional packets for horizontal machining or pallets for clamping vices, electrode holders etc. can be added.

How you benefit - At a glance:

- Easy and quick configuration of the H 1000 clamping system

- 6 different plate sizes offering various clamping options for mould and ejector plates

- Fully automatic calculation of required clamping elements

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]