When plastics are melted, temperatures of several hundred degrees Celsius are reached. Here, the insulation boards support the thermal separation of the temperature-controlled mould from the injection moulding machine. In general, the insulation boards are mounted between the mould clamp plate and the machine clamp plate. This prevents unhindered heat transfer to the machine and keeps the heat in the mould. Heat in the machine leads to inaccuracy and unstable processes.

Area of application

The use of insulation boards shortens the heating process of the mould and leads to homogeneous temperature conditions in the production process. By insulating the moulds, less heat and thus energy is released into the surrounding area and machine, saving energy costs.

Parallelism

The greatest precision possible is essential for things to run smoothly when using insulation boards. At Meusburger, the insulation boards are high-precision ground so they have a standard parallelism of 0.02 mm along the entire surface.

This allows the two mould halves to be moved together in unison, which in turn ensures that the split line face closes cleanly and precisely. Mould halves that are not aligned parallel to each other lead to wear on the guiding and centring elements. Even under the high closing force of the injection moulding machine, the insulation boards do not warp thanks to their strength of 330 N/mm² and 600 N/mm².

Outer insulation with E 1450 - Lattice pattern insulation board

These boards are installed as mould covering outside the mould base so the temperature in the mould can be kept constant. The insulation boards are also optimally matched to the Meusburger standard cavity plates and allow for easy installation.

Due to the lattice pattern of the insulation boards, air cushions are formed between the board and the cavity plate. Since air is a very poor conductor of heat, the heat conduction is significantly reduced by the air cushions created. That is how a homogeneous processing temperature can be maintained and even better, energy savings can be achieved.

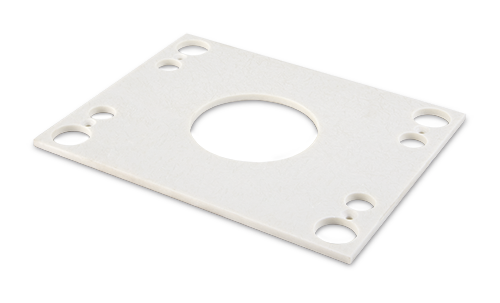

Ready-to-use pre-drilled insulation boards

Due to the already drilled holes, dismantling the mould is possible without removing the insulation board. They are optimally adapted to the standardised Meusburger mould bases and can be quickly used.

Insulation boards according to customer drawing

On request, Meusburger can also custom manufacture the insulation boards completely according to the customer’s drawing. The boards are milled, drilled, labelled and the thickness ground to size exactly according to specifications.

Our high-grade, universally usable insulation boards are available in strengths 330 N/mm² and 600 N/mm² and are also available in a lattice pattern version.

Technical specifications

| E 1400, E 1402, E 1403, E 1405, E 1407, E 1408 | E 1420, E 1425, E 1440, E 1442 | E 1450 | |

|---|---|---|---|

| Material | Composite from resin bonded glass fibres and fillers | Composite from resin bonded glass fibre fabric | Composite from resin bonded glass fibres and fillers, lattice pattern |

| Density | 1.8 g / cm³ | 1.9 g / cm³ | 1.2 g / cm³ |

| Max. temperature | 230 °C | 220 °C | 200 °C |

| Thermal conductivity (λ) | 0.18 W / mK | 0.19 W / mK | 0.09 W / mK |

| Compressive strength at 23 °C | 330 N / mm² | 600 N / mm² | 100 N / mm² |

| Compressive strength at max. temp. | 110 N / mm² | 340 N / mm² | 80 N / mm² |

| Bending behaviour at 23 °C | 200 N / mm² | 340 N / mm² | 150 N / mm² |

| Tensile strength at 23 °C | 70 N / mm² | 300 N / mm² | — |

| Coefficient of linear expansion | 20 10-6 / K | 15 10-6 / K | — |

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]