Installation example – Sectional view

Standard guiding systems

The standard guiding system is used to guide the two mold halves. It essentially consists of guide pillars, guide bushes and centering sleeves.

The high-quality guiding elements match perfectly to our comprehensive range of cavity plates.

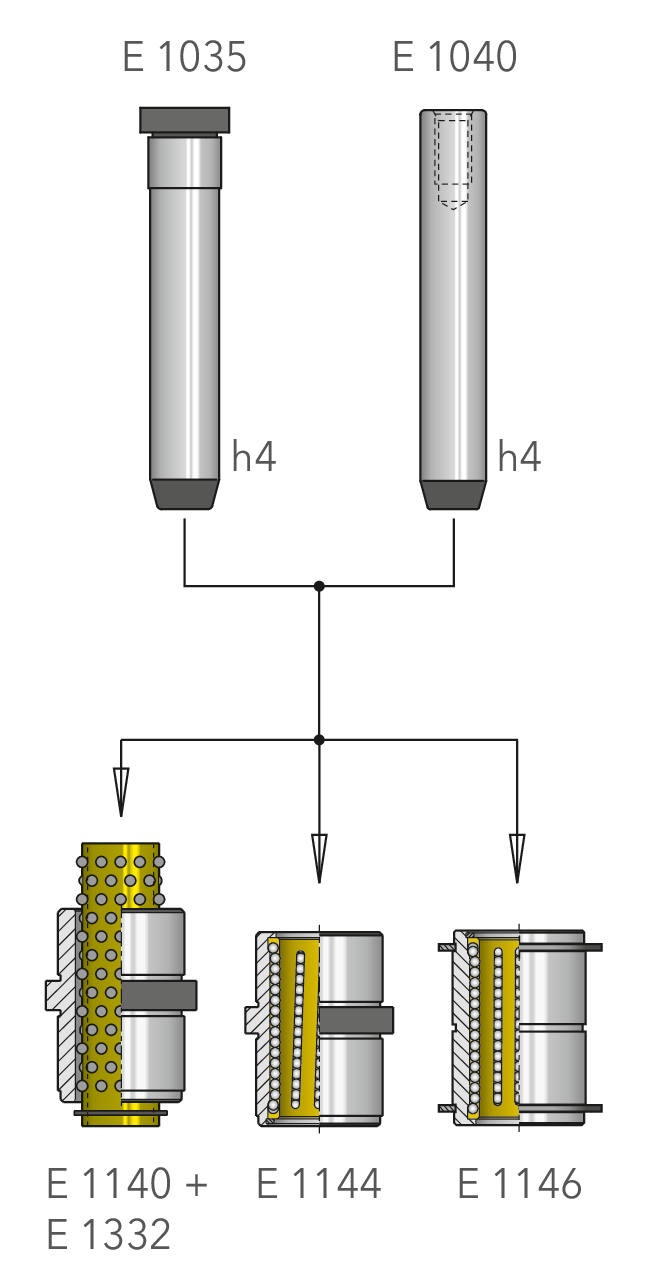

Guiding system with two fitting diameters

- Guiding system with two fitting diameters for an optimal fit in the guiding hole

- Second fitting diameter enables easy assembly and removal

Anti-rotation protection

The correct assembly of the mold halves is guaranteed by the ‘3 + 1’ principal. Three guiding elements with a large diameter and one guiding element with a smaller diameter are installed.

Mold bases designed in the Meusburger web shop have the 3 + 1 principle automatically.

Guiding elements with DLC coating

Guides are subject to high wear due to friction when opening and closing the mold. The DLC coating offers the best sliding properties and thus durability.

Tip: Additional lubrication significantly increases service life.

Tip: Additional lubrication significantly increases service life.

- Increased corrosion resistance and service life

- Best dry-running properties enable use in cleanrooms

- Minimized wear thanks to excellent sliding properties

Ejector set guiding

| NR | V * | FQ ** | Characteristics | Lubrication | |

|---|---|---|---|---|---|

| E 1144 E 1140 + E 1332 |  | high | low |

| VLS 250 high-performance oil |

| E 11206 |  | moderate | medium |

| Relubrication with VLS 250 high-performance oil |

| E 1120 |  | moderate | medium |

| VGS 180 High-performance grease |

| E 1125 |  | moderate | medium |

| Initially with VGM 160 high-performance grease |

| E 11202 |  | moderate | high |

| VGS 180 High-performance grease |

* V: Speed of the ejector set during demolding

** FQ: Permissible shear force

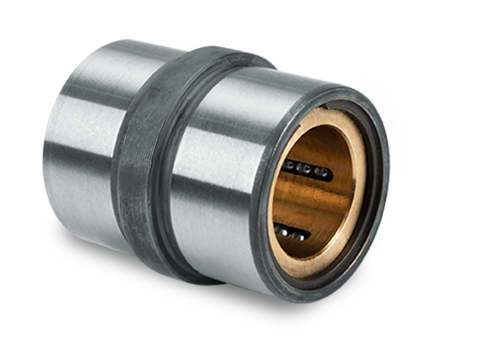

Sliding guide with self-lubricating sinter layer

- Ideal for self-lubricating applications thanks to the oil depot and solid lubricant MoS2 in the sinter layer

- The frictional heat causes the oil to rise to the sliding surface. Due to its capillary action the oil retreats back into the sinter layer (when the machine is idle).

- The ideal diffusion zone between the sinter layer and the steel sheath ensures inseparable molecular bonds

- High resistance to abrasive wear and very good emergency operating features without additional lubrication

Ball guides – precise and smooth running

Flat guiding unit

Flat guiding units are mounted to the outside of the mold. They combine two functions in one component: guiding and centering. The gliding plates are DLC coated as standard.

- Vertical installation from the split line face

Advantage: machining of pocket and thread in one clamping operation - Horizontal installation from the side

Advantage: space-saving installation

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]