购物车 {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} 物料 更换购物篮

备注

| 图片 | 物料 | 件数 | 单价 | 总价 | 总价,含折扣 | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

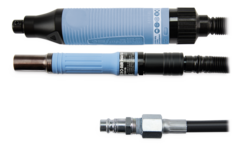

全套 Speed Lap

V 76860

产品描述

- Includes all shapes of the Speed Lap system

- Hard pads and bars for applying diamond compound in order to carry out lapping work

- Supplied in a convenient plastic case

产品选择

| 全套 | 编号 | 价格 / 件数 | 数量 | |||

|---|---|---|---|---|---|---|

|

V 76860/Set | 193.00 € |

|

Product information

Technical tips

E The Meusburger Speed Lap System

The speed lap system comprises of pads and bars for applying diamond compounds in order to obtain high surface quality while saving time.

- New composite material

- Prevents the washing out of soft constituents and the formation of built-up edges

- Higher material removal rate (compared to other lapping techniques)

- Less sensitive to pressure

- Enables consistent, scratch-free lapping

- Sturdy lapping bars

Technical information

- Preparing the lapping pads:

Before using the lapping pads for the first time, use a fine abrasive paper or diamond foil to hone them. - Preparing the lapping bars:

Adjust the lapping bars to the shape of the surface on which you are going to use them; this can be done with sanding discs, abrasive paper or files. You can use a collet to hold circular lapping bars. - Grit:

The optimum grit size is 6 μm but you can also use a coarser grain structure. If required, you can lap to 3 μm. - Lubrication:

You can use VLM 5 Cutting fluid or VLM 20 Polishing oil for thinning the diamond compound. - Pressure:

For 60–70% of this work step, apply light pressure; for the rest of the time, that is: for finishing, do not apply any pressure. - Hand-filing machine:

Speed: 4.000-7.000 min-1

Stroke length: 0.5-1.0 mm

下载

产品推荐

from 72.00 €

正方形 Speed Lap 抛光棒

V 76862

from 27.00 €

高浓度金刚石膏

V 76902

from 66.00 €

基本款天然金刚石研磨膏

V 76905

from 2,052.00 €

微型无刷电动抛光机

GESM 2610

from 558.00 €

优质重型气动锉

GDSF 2020

公司

Quick Links

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]