Kontakt

Vi ger personlig service från måndag till fredag, från 8:00 till 17:00. Via den här länken hittar du kontaktpersonen för din region.

Huvudkontor Wolfurt

+43 5574 6706-0

Varukorg {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Artikel Ändra varukorg

Anmärkning

| Bild | Artikel | St | Enhetspris | Totalpris | Totalt pris inklusive rabatt | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Kunder

- Mould making

- Die making

- Maskin- och fixturbygge

- Konstruktörer

- Formsprutare

- Produkter

- Företag

- Karriär

- Service

Everything you need to know about gas springs: part 1

Publicerad den: 17.11.2020

General information

Choosing the right gas spring among the wide range of products currently available on the market is not easy. Often questions arise such as: How much power do I need? Is this the right size? What do I need to consider for installation or maintenance? And many more. This is exactly where we would like to support you with our four-part series and make the future selection of the right gas spring easier for you.

In the first part of our series ‘Everything you need to know about gas springs’, we provide general information, such as which one is suitable for which application or a comparison with conventional system compression springs.

Design and function

Gas springs are cylinders filled with nitrogen (N2) and use highly pressurised gas for providing the spring force required. Nitrogen is a colourless, odourless and tasteless gas. It is non-flammable and therefore completely harmless. A gas spring is essentially made up of the following three components (the design varies depending on the type):

1 – Piston rod (Superfinish surface)

2 – Bush

3 – Body

All gas springs from Meusburger comply with the Pressure Equipment Directive PED2014/68/EU which came into force in 2016. This directive describes and regulates the requirements for pressure equipment within the European Economic Area.

Gas spring vs. system compression spring

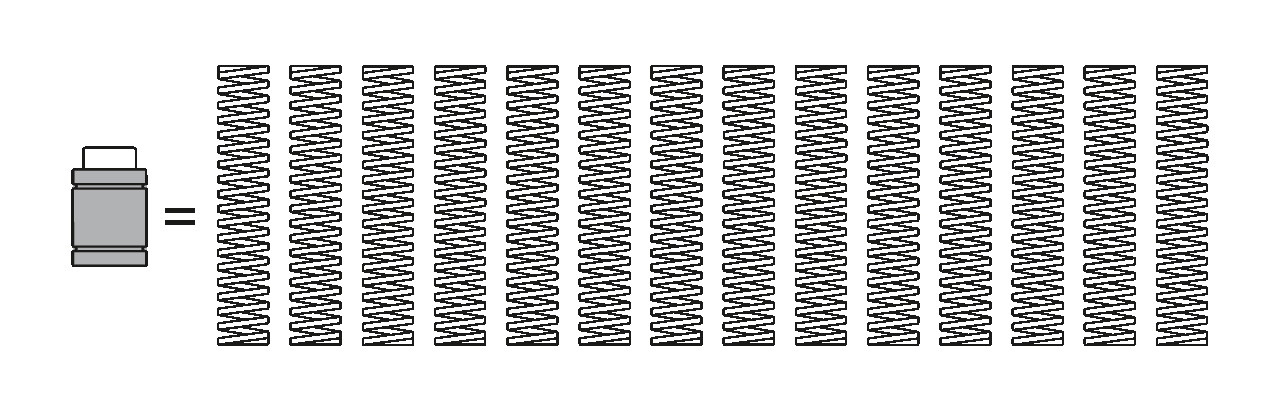

A gas spring requires significantly less space than a system compression spring with the same force.

The full initial force is available at the beginning of the stroke so no preload is necessary.

Information:

The initial force for gas springs is usually given in daN (decanewtons) . This unit corresponds approximately to the weight acting on a mass of 1 kg.

Example: an initial force of 4 daN corresponds to about 4 kg.

In addition, the installation height needed for a gas spring is less than for a system compression spring with the same stroke and force.

Gas springs also have limits

Despite the many advantages already mentioned, there are also limits in the use of gas springs. For example, gas springs can only be used up to a limited number of strokes. Especially for high-performance die-cutting at very high stroke rates system compression springs are still the best option. Due to their more complex construction, gas springs are also usually more expensive than system compression springs.

Företag

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]