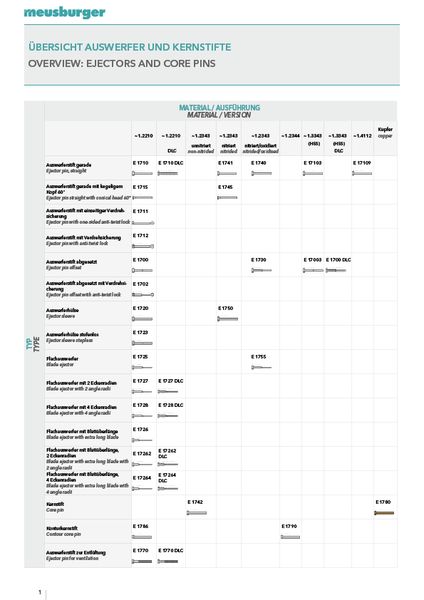

Overview

Are you familiar with our comprehensive range of ejector pins? Through-hardened ejector pins with or without DLC coating, nitrided ejector pins with an oxidation coating, ejectors from HSS as well as contour core pins in various materials are all available from stock.

We would like to inform you about our range of ejectors and core pins below. In addition, you will receive details about the materials and the different variants.

Ejector configurator

Don't waste any time thanks to our ejector configurator.

- Direct ordering of ready-to-use ejectors without enquiry process

- Intuitive and easy to use directly in our digital catalogues

- CAD data of your individual ejector available immediately after configuration

Nitrided-oxidation coated ejectors

- Suitable for applications in die casting and injection moulding

- Oxide layer reduces static and sliding friction

- High corrosion resistance through oxide layer

- Good dry-running properties

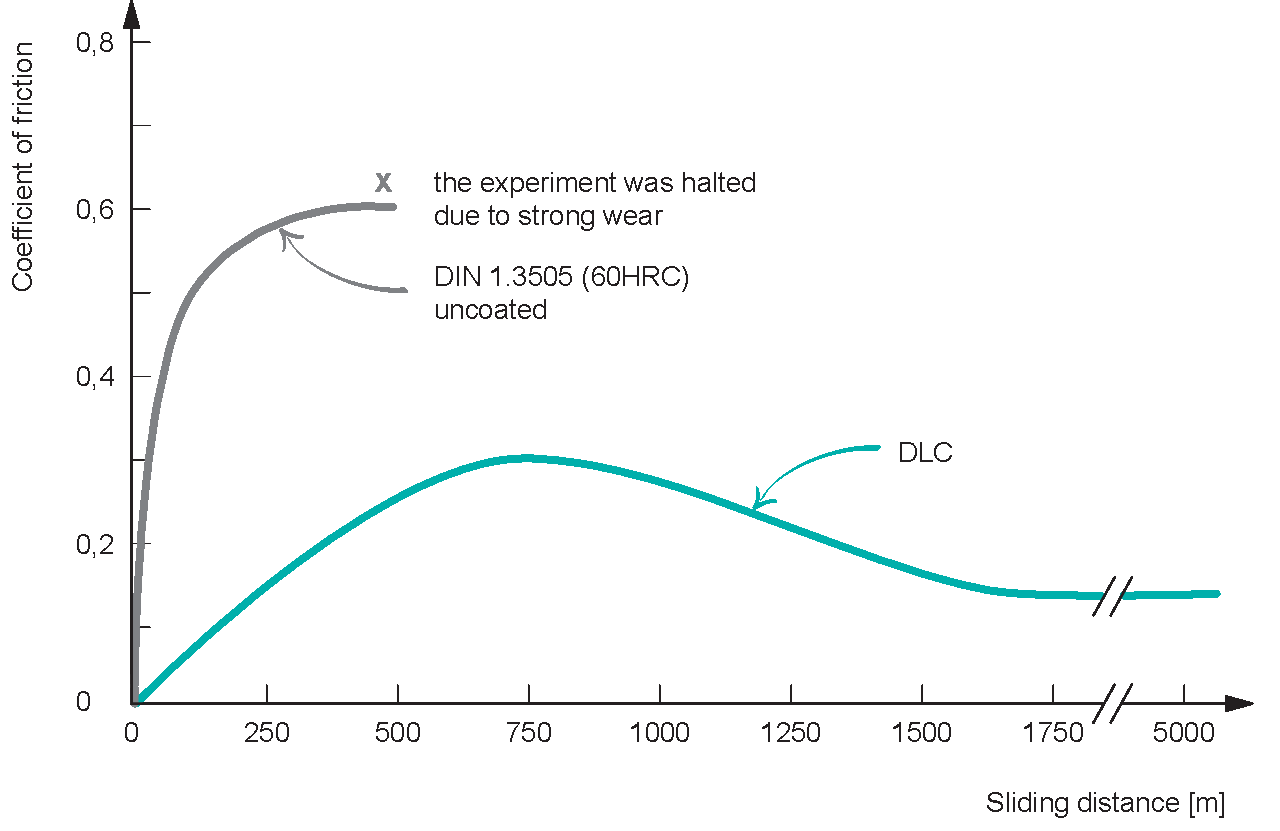

Ejectors with DLC coating

- Increased corrosion resistance and service life

- Guaranteed interchangeability through exact tolerances

- Excellent dry-running properties enable use in cleanrooms

- Minimised wear thanks to excellent sliding properties

- Leave no stains on plastic parts

Ejectors from HSS

- Suitable for high mould temperatures thanks to best high-temperature resistance

- High durability through low wear and high hardness (~ 64 HRC)

- Increased service life when used with plastics with a high glass fibre content

Ejector pin stainless steel

- Especially for use in cleanrooms

- Optimally suited for processing aggressive plastics

Ejectors with anti-twist lock

- Ejector pins with precise anti-twist lock for exact positioning

- Anti-twist lock already provided on the head enabling cost-effective production of contour ejectors

- Two different anti-twist locks with different dimensions available from stock

Ejector sleeves

- Hardened ejector sleeves from 1.2210

- Nitrided ejector sleeves from 1.2343

Ejector sleeves, stepless

The stepless transition from the clearance hole to the guiding hole prevents damage to the ejector and core pins. This can minimise wear, especially in applications where it is necessary to move completely out of the guiding hole.

Blade ejectors

- Ideal for wire-cut openings

- Available with extra long blade for large ejector strokes

- Ready-to-use, high-precision blade ejector pins with 2 or 4 angle radii – with or without extra long blade

- Blade ejectors with radii also available with DLC coating

Ejector pin for ventilation

- Fast, targeted ventilation of the cavity via the ejector pin

- Can be cut to length thanks to ventilation surfaces along almost the entire shaft length

- Optimal guidance of the ejector due to g6 tolerance on the shank

Thanks to the ventilation surfaces along almost the entire shaft, fast and targeted ventilation of the cavity via the ejector pin is possible. The ejector can also be shortened to length if required.

Core pins

- Different core pin types available in different material variations

- Core pin, non-nitrided E 1742 for applications in die casting – easy machining thanks to hardness of 45–48 HRC

- Anti-twist core pins E 1786 and E 1790 – without thickening on shank

Copper core pins

Under thermal stress in the mould, the copper core pins provide rapid heat dissipation. This is particularly advantageous when cooling cores and inserts.

- Fast and targeted cooling of moulded parts thanks to maximum thermal conductivity

- Reduction of cycle time and best part quality due to optimal temperature distribution

- Highest strength due to beryllium-free copper alloy

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]