The decisive advantages of the SP precision die set

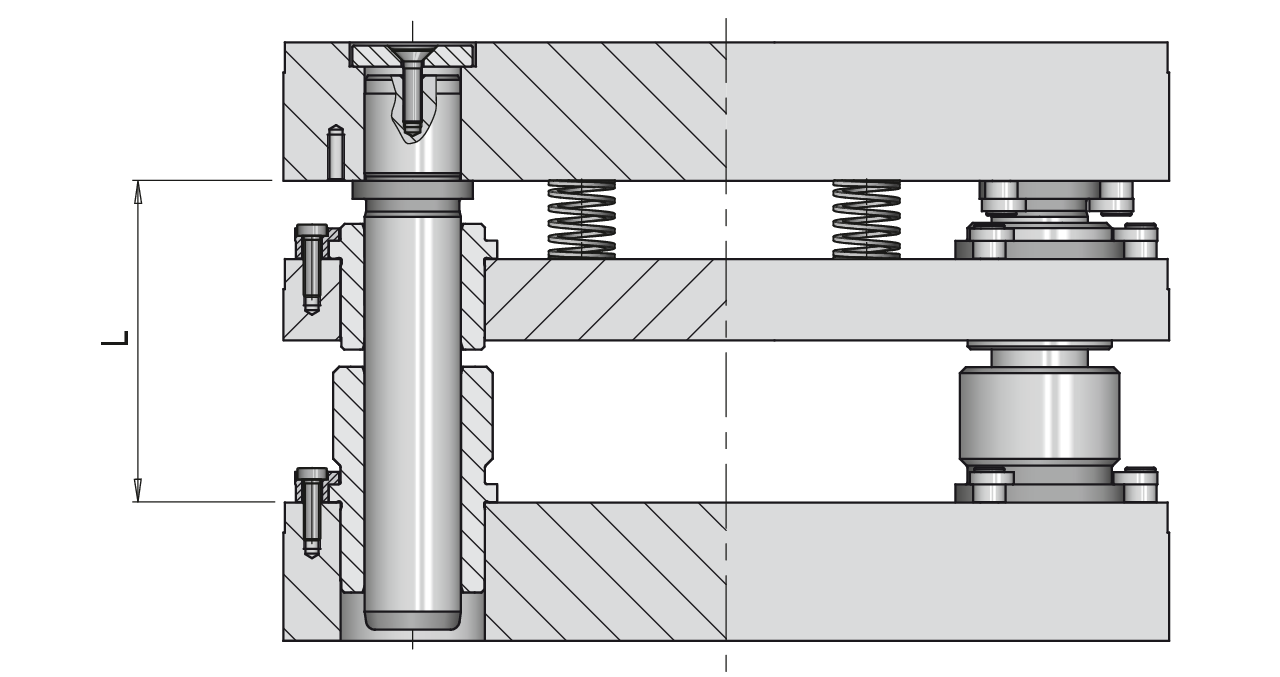

The guide pillar lengths increment in steps of 10 mm in the direction of the upper die and in steps of 20 mm in the direction of the lower die due to the fact that the stroke between retainer plate and backing plate usually varies less than the stroke between the upper and the lower part of the die set.

The guide pillars with center flange can be combined with the ball guiding bushes and three different sliding guide bushes.

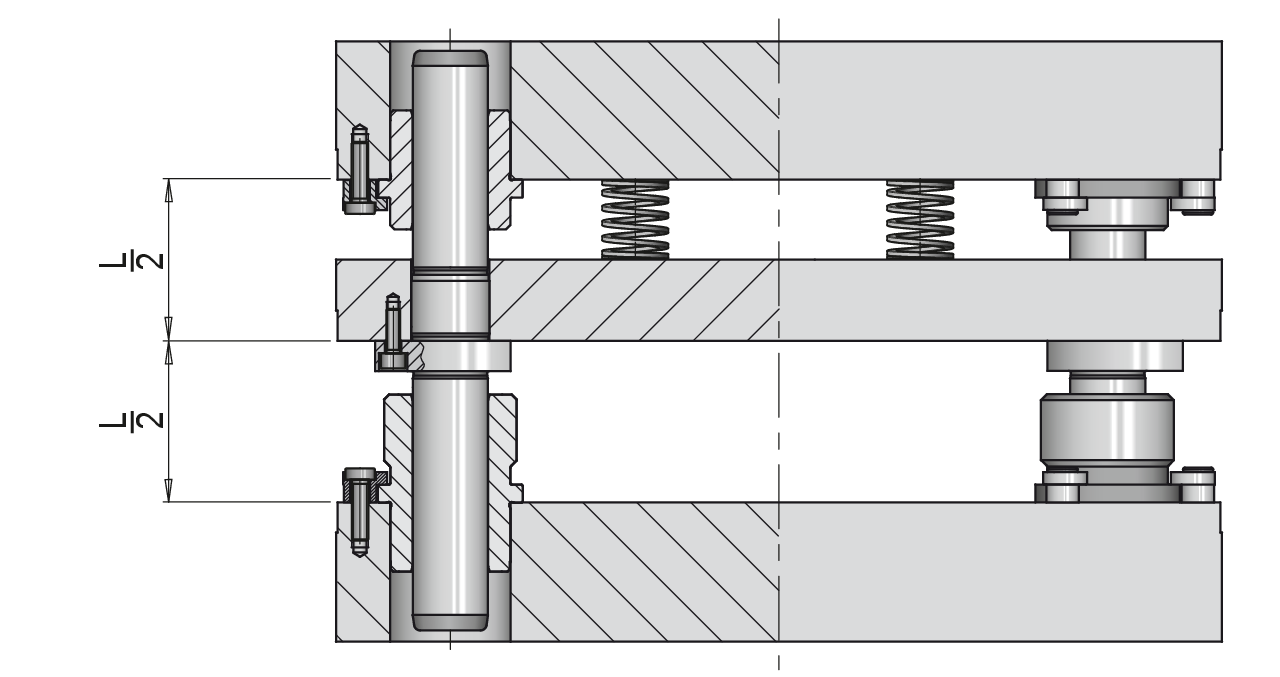

Both length dimensions of the guide pillars, measured from the mounting plane, are nearly the same length. This maximises the advantage of the smallest possible pillar deflection.

- Minimal pillar deflection

- Maximum usable width

- Easy installation of the plates

- Optimal length of the guide pillars

Advantages over SV-Standard die sets

Particularly suitable for progressive dies with increased accuracy requirements because the guide pillars are screwed onto the underside of the backing plate, exactly in the center.

The usable area for the same tool dimension is larger since the guiding system is dimensioned smaller.

Easy assembly of a stamping die with guide pillars with center flange since the backing plate in which the guide pillars are attached, are assembled with the retainer plate. Then the upper part of the die is assembled with the lower part.

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]