Επικοινωνία

Βρισκόμαστε στη διάθεσή σας από Δευτέρα έως Παρασκευή από τις 8:00 έως τις 17:00. Πατήστε τον σύνδεσμο και θα βρείτε τους υπεύθυνους επικοινωνίας στην περιοχή σας.

Κεντρικά Wolfurt

+43 5574 6706-0

Καλάθι {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Είδος Αλλαγή καλαθιού

Παρατήρηση

| Φωτογραφία | Είδος | τεμ. | Κόστος μονάδας | Συνολικό κόστος | Συνολικό κόστος συμπεριλαμβανομένης έκπτωσης | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Πελάτεσ

- Mould making

- Die making

- Κατασκευή μηχανημάτων και εξαρτημάτων

- Τμήμα για σχεδιαστές

- Χυτευτής με έγχύση

- προϊόντα

- Εταιρεία

- Καριέρα

- Service

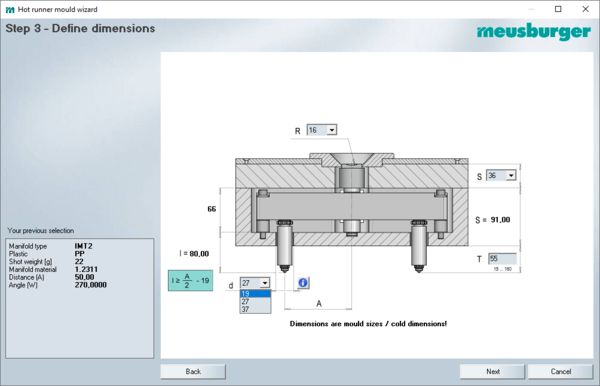

Create your hot runner mould with transparent price display in just a few clicks.

FH configurator update

21.03.2022

New manifold type ‘H’

A new type of manifold was added to our tried and trusted standardised hot runner system. Now the manifold type ‘H’ with four nozzles can also be selected and configured in the hot runner configurator.

- Rheologically balanced system for optimal results

- Individual selection of the gating position via parameters L1 + L2

- Insulating caps now selectable for all gate assemblies

12.10.2020

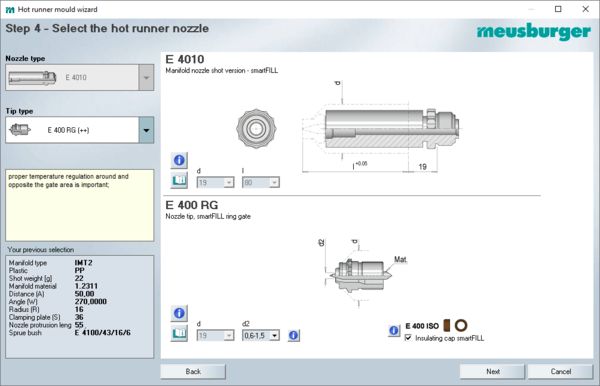

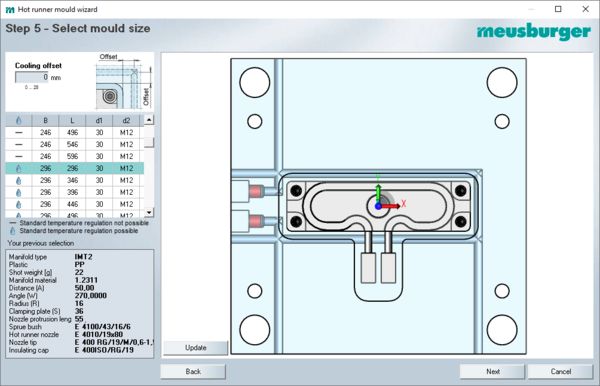

With our mould making update, we also added innovations for the configurator of FH hot runner moulds. We considerably expanded our range of nozzles as well as the selection of plastic materials. Our new functions also allow us to give you a recommendation as to which gate type is best suited for each material selection. The offset for the distance of the cooling hole optimises the mould size suggestion. In the following instructions, we guide you through the innovations and show you the new options.

Surface expansion in the configurator

Selecting the correct gate type

When selecting the gate type, the E 400 RG is set as standard, as this is also the ideal solution in most cases. But we also offer the possibility to switch to another type. To help you with the decision we have included symbols that show you how suitable a specific gate assembly is:

- ++ highly suitable

- ++ well-suitable

- o suitable

If the combination of material and the gate assembly results in a recommendation for an insulating cap, then this can be ordered directly.

Adjusting the offset

The offset of the cooling hole to the manifold cutout can be adjusted in the x and y axis with the same value from 0 to 25 mm. This allows the output of the most and the smallest sizes when selecting the appropriate mould sizes. There are optimised default values for every manifold type and manifold size. The safety distances from the cutout to the outer edge have been optimised.

In the course of the upgrade, the internal processes were considerably optimised. This is reflected in the much wider selection of products and applications for our customers. In addition, new help functions have been implemented to assist you in selecting the appropriate items.

Εταιρεία

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]