Επικοινωνία

Βρισκόμαστε στη διάθεσή σας από Δευτέρα έως Παρασκευή από τις 8:00 έως τις 17:00. Πατήστε τον σύνδεσμο και θα βρείτε τους υπεύθυνους επικοινωνίας στην περιοχή σας.

Κεντρικά Wolfurt

+43 5574 6706-0

Καλάθι {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Είδος Αλλαγή καλαθιού

Παρατήρηση

| Φωτογραφία | Είδος | τεμ. | Κόστος μονάδας | Συνολικό κόστος | Συνολικό κόστος συμπεριλαμβανομένης έκπτωσης | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Πελάτεσ

- Mould making

- Die making

- Κατασκευή μηχανημάτων και εξαρτημάτων

- Τμήμα για σχεδιαστές

- Χυτευτής με έγχύση

- προϊόντα

- Εταιρεία

- Καριέρα

- Service

Are you interested in our company and our products? Then you’re in the right place.

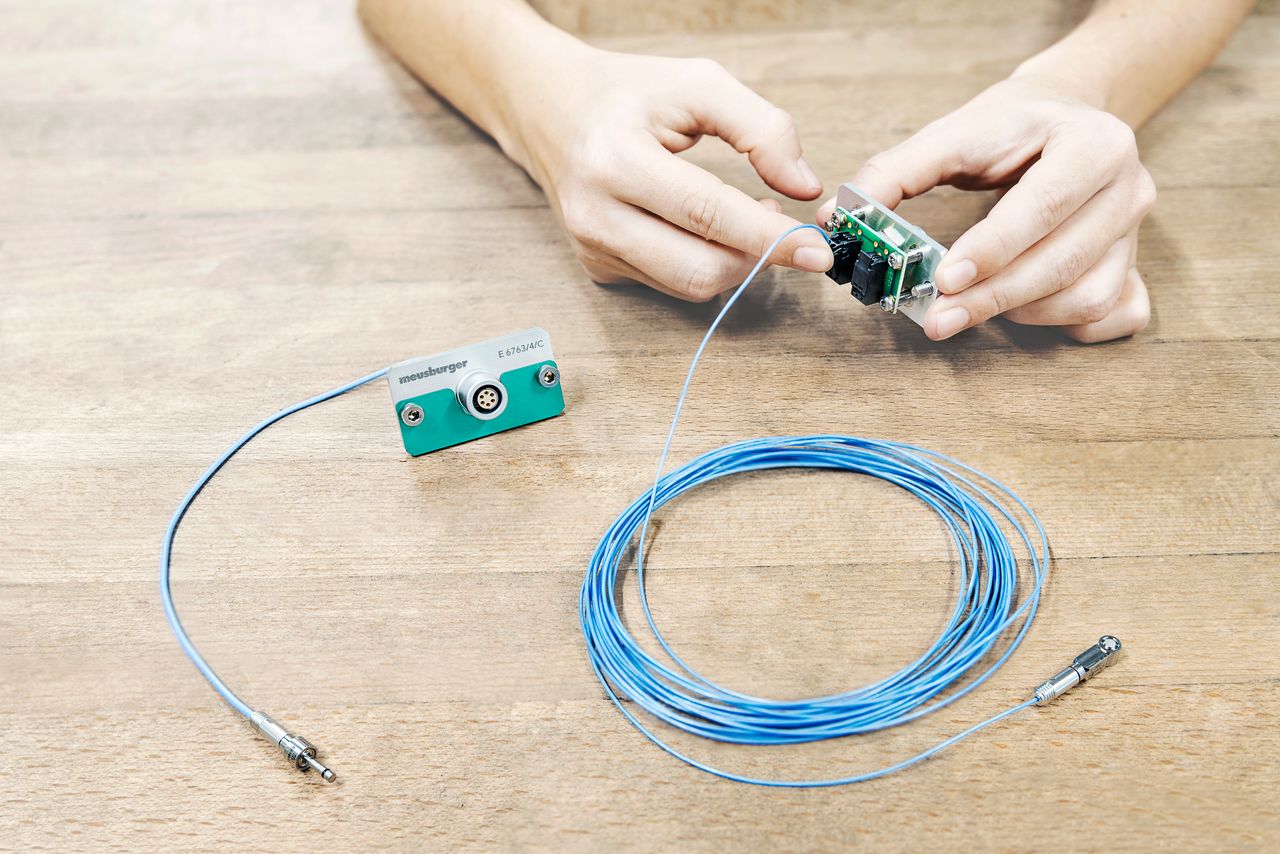

Cavity pressure sensors: single wire vs. coaxial

15.05.2020, Κατασκευή καλουπιών μορφής

The cavity pressure is an important parameter in process monitoring during plastic injection moulding. Pressure sensors are therefore indispensable for comprehensive mould monitoring. The use of high-quality piezoelectric sensors leads to optimal process quality and increases part quality sustainably. Two different technologies are available on the market for charge transfer: single wire and coaxial cables. We will show you the essential differences and characteristics of these two variants.

Single wire

The single wire cable has a very small diameter. This means it can be routed flexibly with minimal bending radii in cable slots and holes and shortened as required. These cables are therefore ideally suited for moulds with limited space. In single wire technology, the mould provides shielding from the surrounding environment such as other voltage sources.

Coaxial

The coaxial cable is characterised by optimal shielding against external signals thanks to its steel sheath. The use of cavity pressure sensors with a coaxial cable is therefore ideally suited for moulds with a high number of electrical components, such as hot runner components or monitoring equipment. This variant is also used if the cable is routed outside of the mould. With the mini coaxial version, several sensor signals can be combined on one multi-channel connector.

Comparison of the two versions available at Meusburger for multi-channel connectors

| Single wire E 6760 | Mini coaxial E 6757 | |

| Signal | Can be disturbed by signals from the environment (noise) if the shielding is insufficient | No signal interference thanks to shielding against environmental influences through steel sheath |

| Cable length | Available in lengths 2,000 and 5,000 mm; cables can easily cut to length as required | Available in consecutive lengths from 200 to 1,000 mm; can only be cut to length with a special tool |

| Cable diameter | 1.2 mm | 1.9 mm |

| Flexibility | Very flexible due to minimal bending radii but risk of kinking | Less flexible than single wire cable, but resistant to kinking |

| Installation | Easy to install thanks to the insulation displacement connector on the multi-channel connector | Easy to install thanks to mini coax female connector on the multi-channel connector |

| Price | Lower than for mini coaxial | Higher than for single wire |

Multi-channel connector

With the E 6763 multi-channel connector, the signals from 4 to 8 cavity pressure sensors can be combined with minimum cabling effort. Depending on the version, the multi-channel connectors have insulation displacement contacts for the single wire cable (version S) and mini coax female connectors for the mini coaxial cable (version C). The mould recognition is done by a chip integrated on the circuit board and enables high process reliability during mould changes. In addition, the sensor data can be easily identified with the supplied labelling plate.

Connection options

The different connection options for direct and indirect cavity pressure sensors are shown in the following figures.

Cavity pressure sensor connection options – direct

Cavity pressure sensor connection options – indirect

Available from stock at Meusburger

In addition to the existing range of cavity pressure sensors, Meusburger now offers the single wire and mini coaxial cables as well as the matching multi-channel connectors from stock. For efficient mould design, the CAD data for the multi-channel connectors and installation spaces is immediately available.

Press contact

Should you require further information on this press release or have any questions or comments, please feel free to contact us by email.

Julia Jakob

Communication/public relations+43 5574 6706-1496

Εταιρεία

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]