Επικοινωνία

Βρισκόμαστε στη διάθεσή σας από Δευτέρα έως Παρασκευή από τις 8:00 έως τις 17:00. Πατήστε τον σύνδεσμο και θα βρείτε τους υπεύθυνους επικοινωνίας στην περιοχή σας.

Κεντρικά Wolfurt

+43 5574 6706-0

Καλάθι {{ (warenkorbCtrl.warenkorb.bestellNummer ? (' [' + warenkorbCtrl.warenkorb.bestellNummer + '] ') : '' )}} | {{warenkorbCtrl.warenkorb.items.length}} Είδος Αλλαγή καλαθιού

Παρατήρηση

| Φωτογραφία | Είδος | τεμ. | Κόστος μονάδας | Συνολικό κόστος | Συνολικό κόστος συμπεριλαμβανομένης έκπτωσης | |

|---|---|---|---|---|---|---|

|

|

{{warenkorbItem.produktgruppe.produktname}}{{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben:[{attrPrefix: 'L_', searchPattern: '/...', replacePrefix: '/', replaceSuffix: ''}] }} {{warenkorbItem.bezeichnung | artikelBezFilter:warenkorbItem.attributwertEingaben}}

{{attributwertEingabe.attributBezeichnung}}

|

|

||||

{{hannexItem.Benennung}}{{hannexItem.Bezeichnung}} |

|

-

Πελάτεσ

- Mould making

- Die making

- Κατασκευή μηχανημάτων και εξαρτημάτων

- Τμήμα για σχεδιαστές

- Χυτευτής με έγχύση

- προϊόντα

- Εταιρεία

- Καριέρα

- Service

Are you interested in our company and our products? Then you’re in the right place.

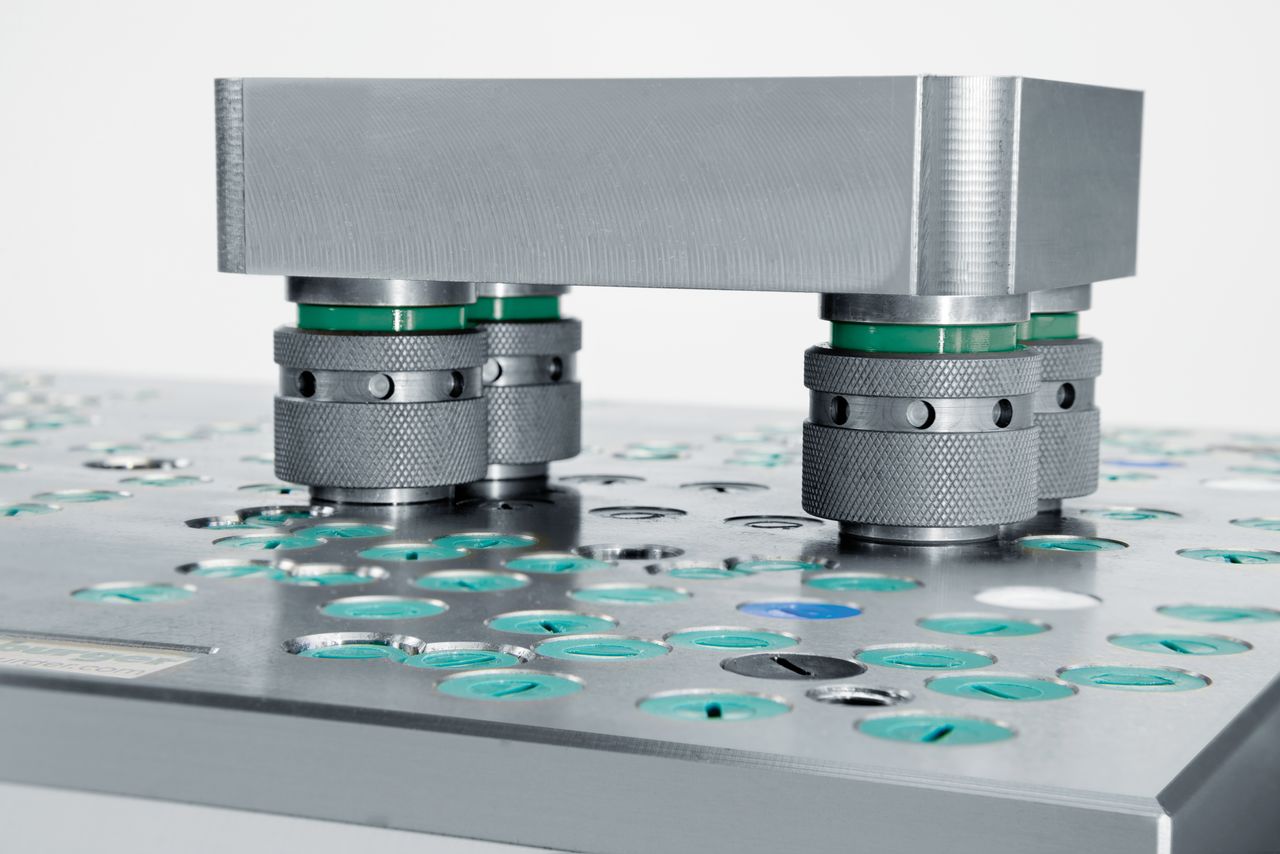

The multifunctional clamping system for mould making

25.04.2024, Κατασκευή καλουπιών μορφής

With the clamping system H 1000 by Meusburger, customers will not only work quickly and efficiently, but also with absolute and repeatable accuracy. The standard parts are aligned and clamped where it matters for the mould function, i.e. in the guiding holes.

In-house development from Meusburger

The clamping system H 1000 is an innovative in-house development from Meusburger that enables precise clamping in the µ range with repeatable accuracy. Thus, customers not only increase the quality of their moulds, but they also reduce their lead times thanks to shorter set-up times. The standard parts manufacturer offers six different plate sizes that are available from stock together with the matching accessories. The clamping scheme is included in the delivery. Thanks to the stress-relieving heat treatment of the plates in the in-house furnaces of Meusburger as well as the strict quality checks, customers benefit from optimum quality. Moreover, the clamping system needs to be aligned only once to determine the zero point for the X and Y axes. The H 1000 can be used both on milling centres and on EDM machines.

Clamping of inserts

The tried and trusted clamping system H 1000 from Meusburger also enables the clamping of inserts. Any number of clamping supports with centring can be fixed to the fitting holes of the H 1000 with base plate. In the insert, the clamping spigots are introduced into provided fits with a thread. Clamping spigots with an undersized fit are available for machining before hardening. Now the insert is simply placed onto the clamping support and tightened with locking sleeves. Five sides of the workpiece remain free from interfering contours. The distance to the base plate can be increased in 40 mm steps in combination with the centring support extension piece H 1030. As the clamping supports clamp centrally, repeatability in the μ range is guaranteed.

Flexible clamping according to position

Workpiece clamping can be done in multiple ways. The clamping supports H 1080 by Meusburger enable easy clamping of inserts and small to medium-sized workpieces. In combination with the clamping plate H 20100, flexible clamping of workpieces according to their position is possible within a 20 mm hole grid. Thanks to the high-precision alignment edge, the clamping plate only needs to be positioned once on the machine table. Then the clamping supports are positioned within the hole grid, which enables workpiece clamping with repeatable accuracy. Set-up times are shortened considerably, which in turn leads to reduced lead times, and programming is simplified due to clamping without interfering contours.

Press contact

Should you require further information on this press release or have any questions or comments, please feel free to contact us by email.

Julia Jakob

Communication/public relations+43 5574 6706-1496

Εταιρεία

Meusburger Georg GmbH & Co KG

Kesselstr. 42

6960 Wolfurt | Austria

+43 5574 6706

office@meusburger.com

@ 2024 Meusburger

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2024 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Österreich [DE]

Österreich [DE]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]